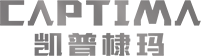

China wholesale Bag-In-Box Pouch Bag Making Machine Manufacturers – SKB450-Z High Speed Center Seal Bag Making Machine – CAPTIMA

China wholesale Bag-In-Box Pouch Bag Making Machine Manufacturers – SKB450-Z High Speed Center Seal Bag Making Machine – CAPTIMA Detail:

Product Features

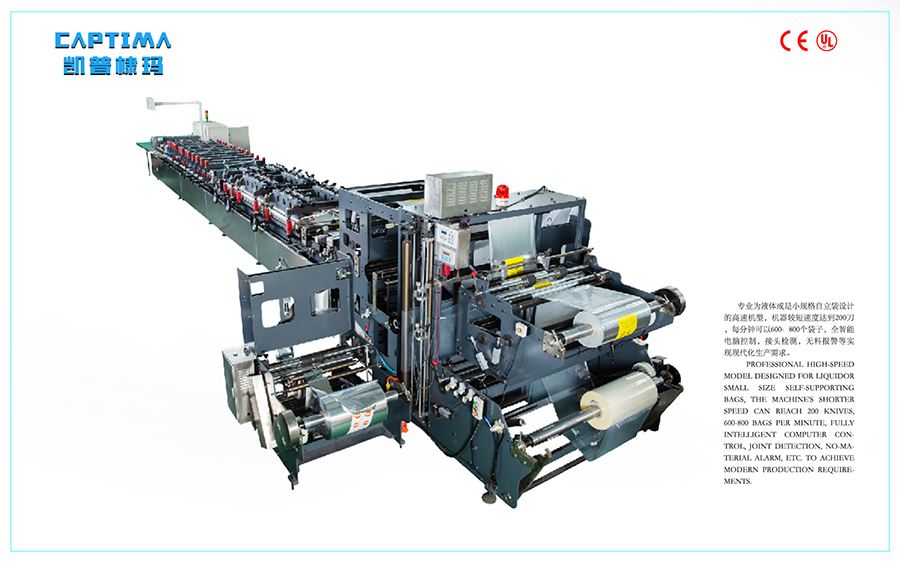

The high-speed model of middle seal, four seals, and three seals has a simple design structure, which is different from the traditional mechanical structure, and realizes the production of all specifications without guide plates.

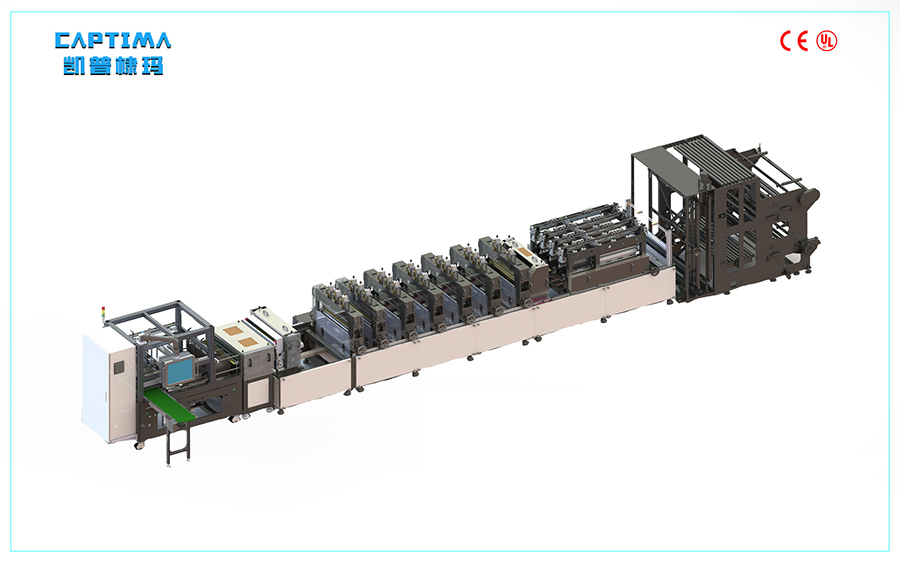

Product Picture

Sample Bag Picture

Product Packaging Scope

Machine Configuration

| Model | SKB450-Z High Speed Center Seal Bag Making Machine | |||||

| Optional Model | 450 | 600 | Customization | |||

| Film Material | CPP,PET,OPP,PAPER and all kinds of laminating films | |||||

| Film Size | Max. Width:900mm、Max. Diameter:φ800mm | |||||

| Rewinding Form of Film | Horizontal Film Axis Type • Closed Palm Feeding Mode • Tension Control Magnetic Brake, Non-stop unwinding matching Automatic Joint Detection Function

AC Motor Driving System with inverter Detection of printing color label by color label sensor |

|||||

| Bag-making Function | Single line center seal,Single line four side seal,Single line center seal with side gusset | |||||

| Bag-making speed | 200shots/min | Unwind line Speed: | 40m/min | |||

| Bag-making Size | Bag length:80-400mm,Bag width:50-450mm,Gusset depth:20-70mm | |||||

| Skip feed function | 400 mm for one time, more than 400mm, used skip feed feature, maximum is 6times | |||||

| Bad exclusion function | At the beginning of operation, in order to prevent the incorporation of bad heat sealing bags, a film with arbitrary distance is set from the cutting knife to remove double feeding. | |||||

| Electrical Matching | Host Frequency:1set,3KW(SEW)

Traction servo motor:2set,1.5KW—1set,1.0KW—1set. Feeding AC motor:1set,0.4KW—1set. Feeding inverter:1set,0.75KW—1set. |

|||||

| Electrical Matching | Total Power:

32KW,380V,50HZ |

Cooling Water:

10L/min |

Air Pressure:

0.6MPa(6Kgf/)cm² |

|||

| Machine Dimensions | L*W*H:11000*1500*1700mm (By the selected function to determine the final size) | |||||

|

Option function |

three side seal | Double cutter (including round corner punches). | ||||

| Main web with non-stop function | Fully automatic coffee valve | |||||

| Fully automatic on-line die cutting | CCD Cutter | |||||

| New Model | Ultra-high speed hostless center seal bag making machine (300 shots/ min)

Automatic Detection Bag Strapping Machine |

|||||

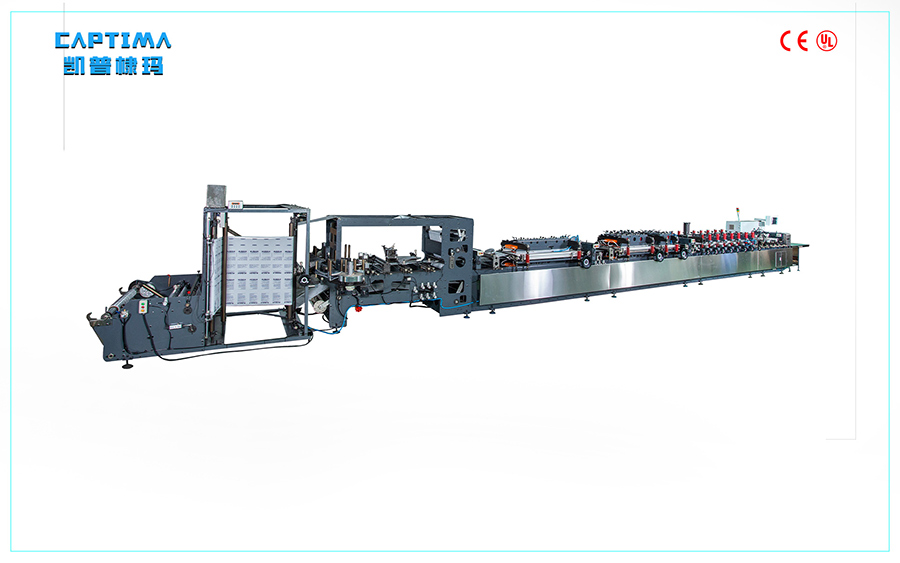

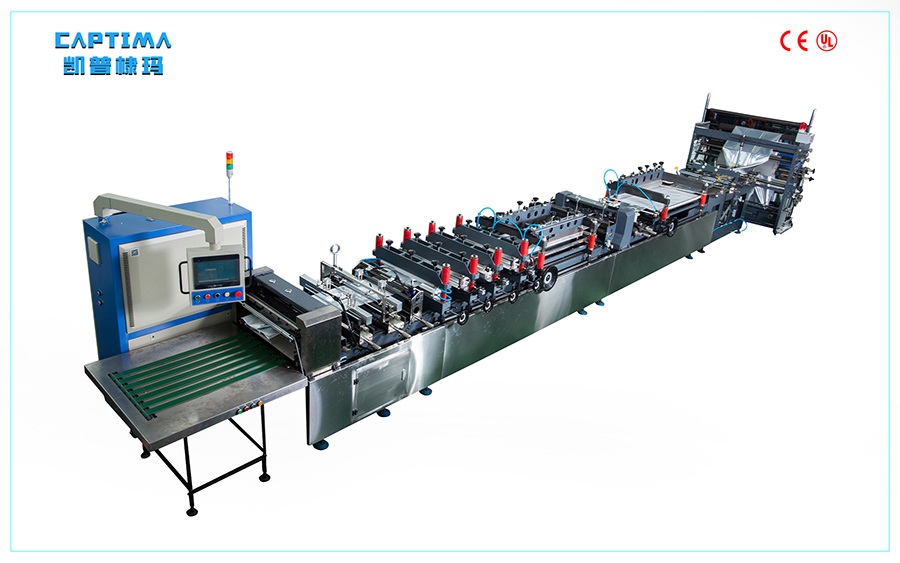

Machine Parts Diagram

Unwinding with constant tension is controlled by the frequency converter, and EPC is used to correct the deviation to the center working position

The forming part of the middle seal and four-side seal adopts “aluminum drum structure” to reduce traction and friction, increase the speed of bag making, and reduce the surface wear rate of the material by nearly 95%. The forming part of several plastic bags is completed by the same set of devices at one time. There is no need to replace the templates for different specifications, reducing the difficulty of operation and debugging time, and improving the work efficiency of operators

The horizontal seal adopts multiple sets of high pressure and low temperature forms, which is suitable for low temperature and high speed production of different thicknesses and different materials. The system is updated to a mode that increases a certain range of speed without increasing the temperature, reducing the work steps of the operator and saving debugging time

The camera controls the double cutter structure, the high-definition lens accurately locates the cutting point, and the cutter performs high-speed and stable cutting action to ensure that the bag-shaped radius is complete and beautiful, reaching the accuracy standard of the die-cutting machine. Working speed: 200 cuts per minute .

Product detail pictures:

Related Product Guide:

Well-run equipment, specialist income crew, and better after-sales services; We're also a unified major family, anyone stay with the organization value "unification, determination, tolerance" for China wholesale Bag-In-Box Pouch Bag Making Machine Manufacturers – SKB450-Z High Speed Center Seal Bag Making Machine – CAPTIMA , The product will supply to all over the world, such as: California, Vancouver, Oman, To work with an excellent items manufacturer, our company is your best choice. Warmly welcome you and opening up the boundaries of communication. We are the ideal partner of your business development and look forward to your sincere cooperation.

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!