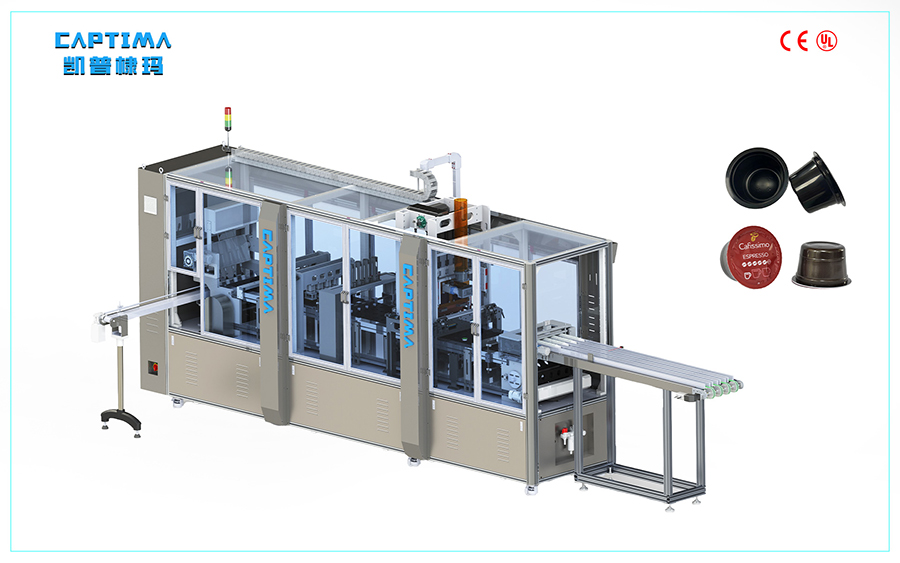

China wholesale 100 Holes Capsule Filling Machine Factory – Commercial Capsule Filling Machine CFM-6 Caflssimo Automatic Packaging Powder Espresso Cup – CAPTIMA

China wholesale 100 Holes Capsule Filling Machine Factory – Commercial Capsule Filling Machine CFM-6 Caflssimo Automatic Packaging Powder Espresso Cup – CAPTIMA Detail:

Product Features

1. Automatic rejection of defective products

2. Nitrogen filling and fresh-keeping function (residual oxygen content ≤0.8%)

3. Full servo filling system

4. Full-line non-stop feeding

5. Fixed number production function

6. Closed-loop weighing control system

7. Food contact Partially uses food grade 304

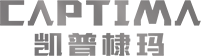

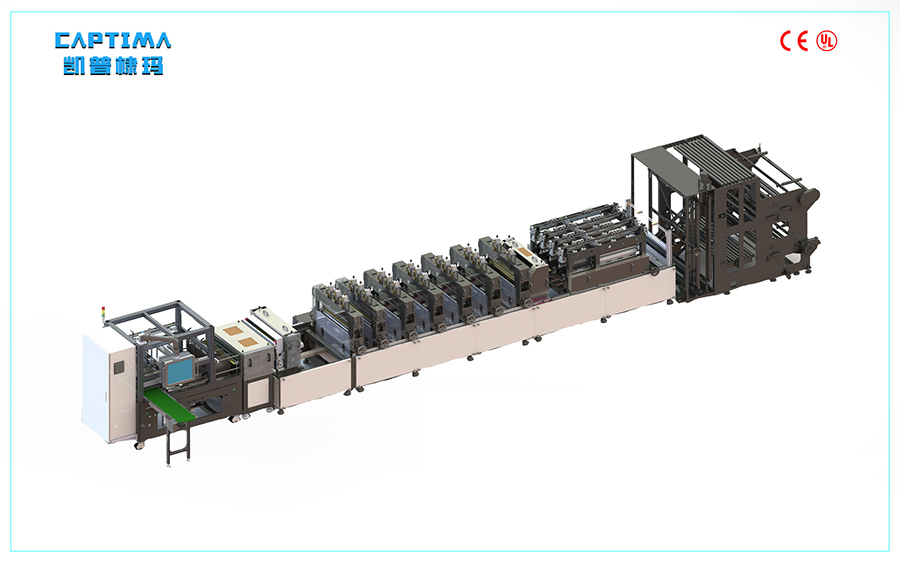

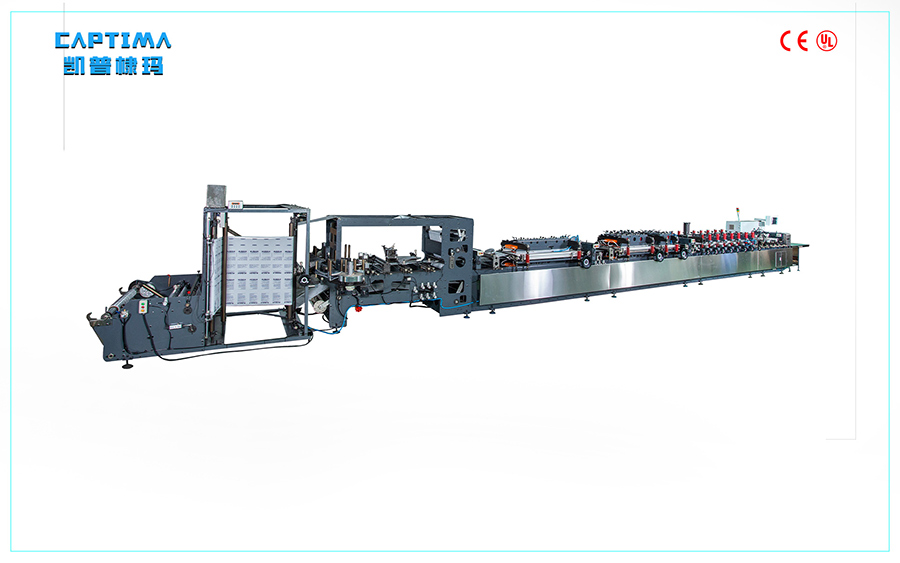

Product Picture

Sample Bag Picture

Product Packaging Scope

Machine Configuration

| Product number | CFM-6 |

| Applicable cup type | Espresso Cup/K-Cup (customizable) |

| Sealing material | Pre-cut aluminum foil film |

| Control System | PLC+bus communication |

| Total power | 220V/50Hz (voltage can be customized) |

| Gas demand | 0.7Mpa |

| Overall line efficiency | 160 p/m (40p/l/p) |

| Filling accuracy | 20g±0.15g (powder) |

| Filling method | Servo custom screw |

| Applicable raw material characteristics | Powder granule liquid |

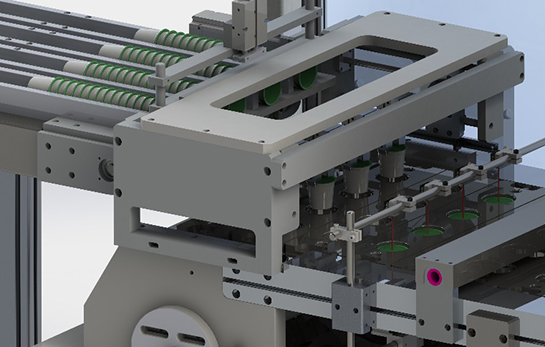

Machine Parts Diagram

Drop Cups Structure

Option 1:

Straight-line drop cups pass through the straight-line feed tube, each tube working time is only 15 minutes (estimated 300-400 cups), low material level automatic alarm call through buzzer, manual feeding.

Option 2:

Horizontal conveying cup body structure, 0-shaped belt conveying is controlled by a discharge motor, machine speed is synchronized with the speed of the canning line body, the storage structure adopts a warehouse body to save the manual feeding cycle and time to the greatest extent, and can achieve a single feeding Time is controlled at every 1.5 hours

Option 3:

Centrifugal disc structure, rotating conveying synchronous canning line speed, the storage structure adopts the silo body to save the manual feeding cycle and time to the greatest extent, and can achieve a single feeding time controlled at every 3 hours, which is suitable for “fully automatic Production line demand”.

Rejection Of Defective Products

The canned products are determined by the second weighing, and the defective products are mechanically rejected by the chain plate structure.

Rejection Of Defective Products

Swing Output Armer

Swing Output Armer

Swing armer to pickup the capsule out, then return to packaging.

Application

Product detail pictures:

Related Product Guide:

We offer fantastic energy in high quality and enhancement,merchandising,profits and promoting and procedure for China wholesale 100 Holes Capsule Filling Machine Factory – Commercial Capsule Filling Machine CFM-6 Caflssimo Automatic Packaging Powder Espresso Cup – CAPTIMA , The product will supply to all over the world, such as: Romania, Seattle, Somalia, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.