China wholesale Capsule Machine Size 2 Pricelist – High Speed Primary Packaging Capsule CFM-1 Captima Filling And Sealing Machine K-Cup One Line – CAPTIMA

China wholesale Capsule Machine Size 2 Pricelist – High Speed Primary Packaging Capsule CFM-1 Captima Filling And Sealing Machine K-Cup One Line – CAPTIMA Detail:

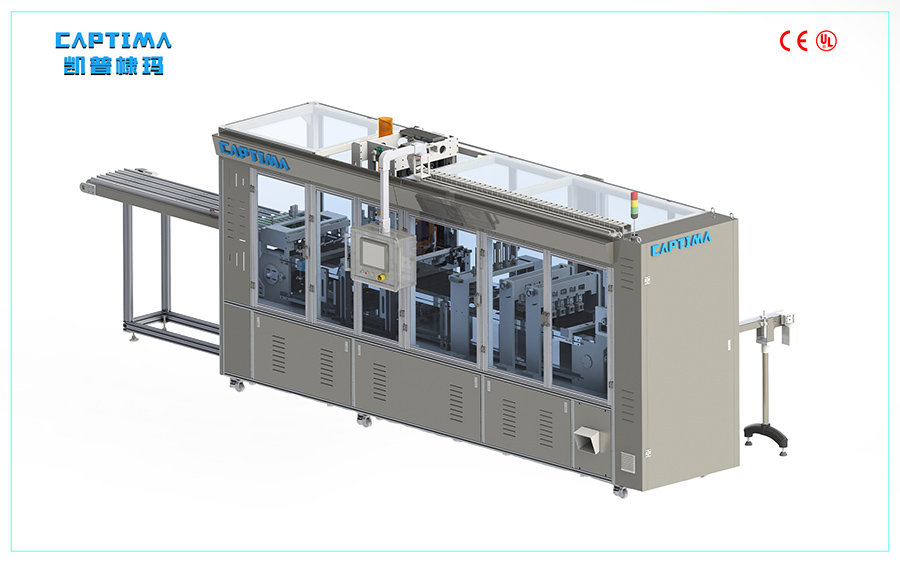

Product Features

1. Automatic rejection of defective products

2. Nitrogen filling and fresh-keeping function (residual oxygen content ≤0.8%)

3. Full servo filling system

4. Full-line non-stop feeding

5. Fixed number production function

6. Closed-loop weighing control system

7. Food contact Partially uses food grade 304

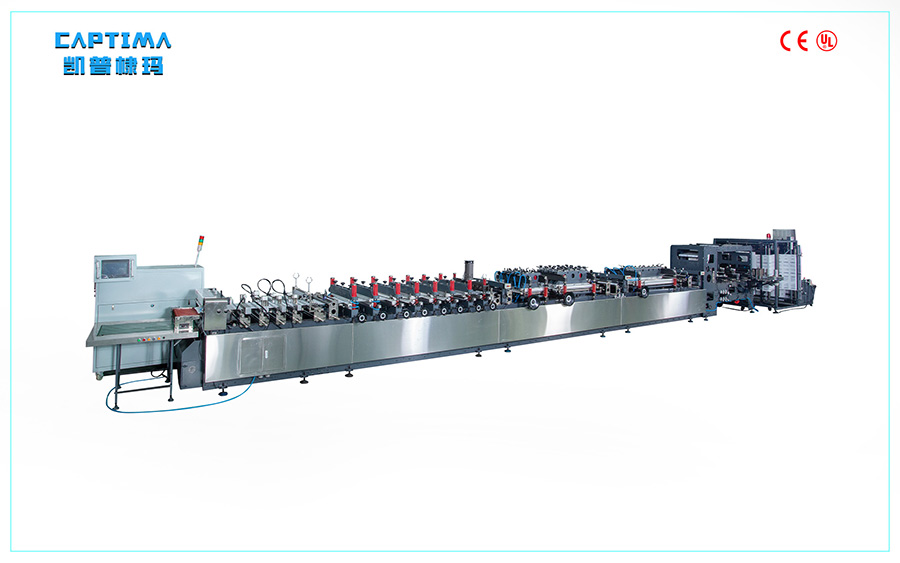

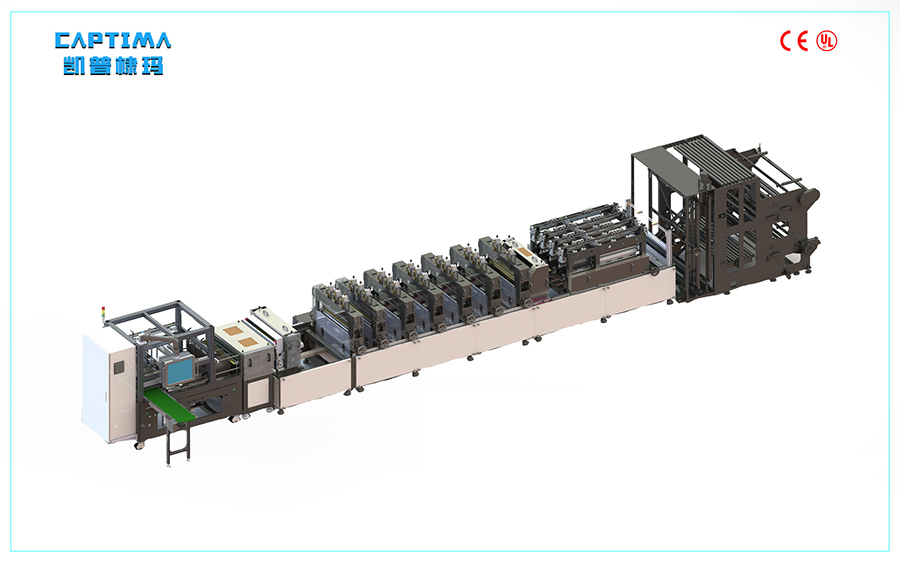

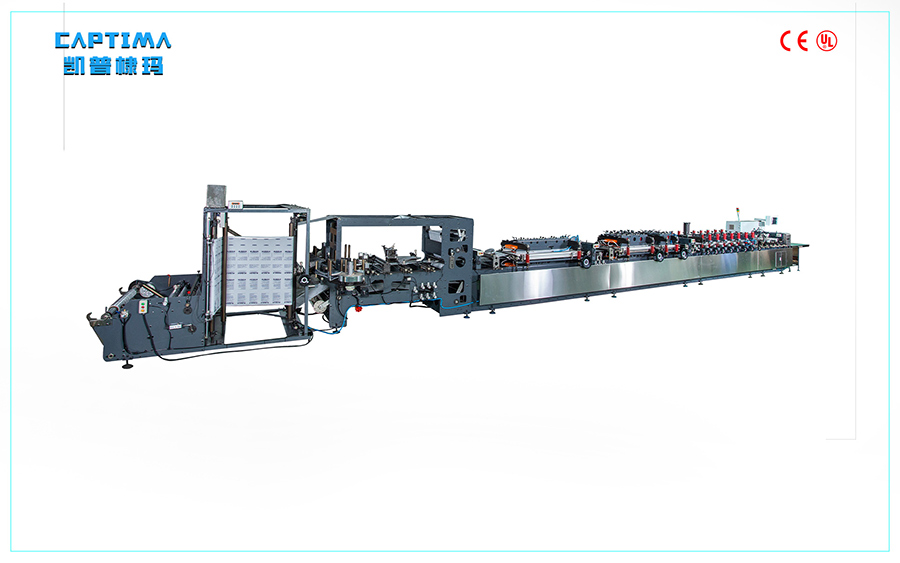

Product Picture

Sample Bag Picture

Product Packaging Scope

Machine Configuration

| Product number | CFM-1 |

| Applicable cup type | K-CUP/Dolce gusto espresso/nesspresso (customizable) |

| Sealing material | Aluminum foil film |

| Mechanical speed | 40 cups/min |

| Canned quantity | 15g |

| Canning accuracy | ±0.2g |

| Nitrogen consumption | 150L/min |

| Control System | PLC+bus communication |

| Total power | 220V/50Hz (voltage can be customized) |

| Gas demand | 0.7Mpa |

| Overall line efficiency | 160 p/m (40p/l/p) |

| Filling method | Servo custom screw |

| Applicable raw material characteristics | Powder granule liquid |

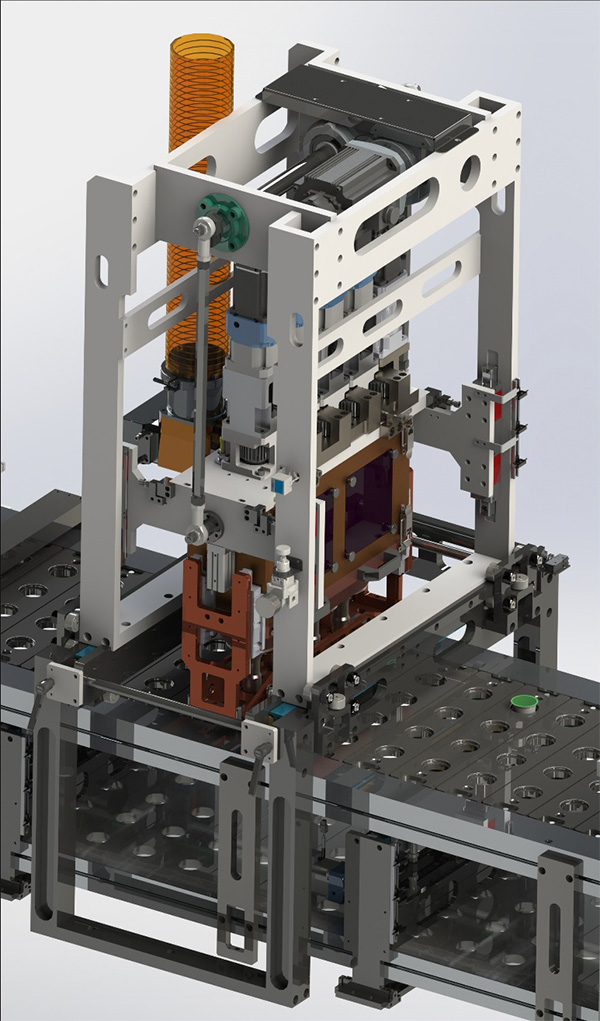

Machine Parts Diagram

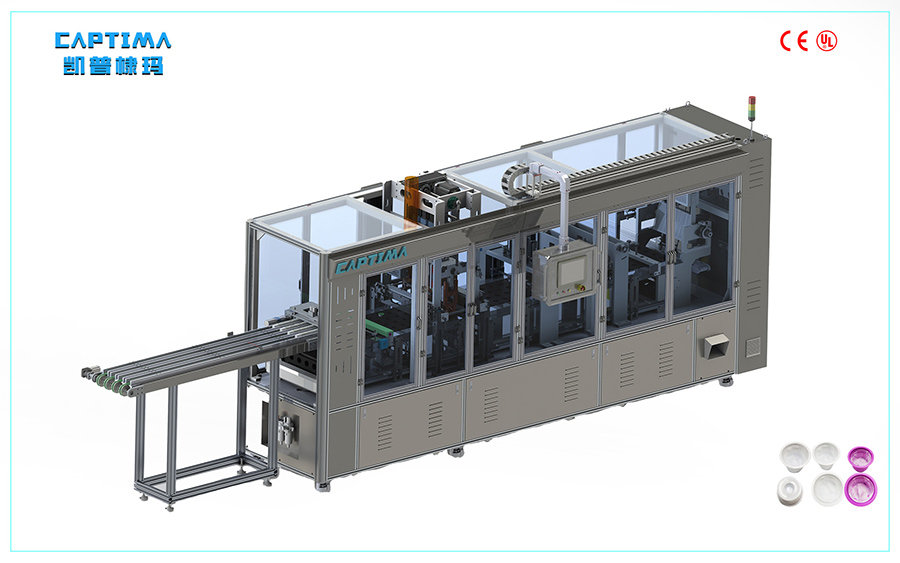

Filling Structure

Ensure sanitation, full servo screw filling system

Filling system adopts full servo drive control, only need to manually set the filling amount, without complex setting can achieve a key parameter adjustment. Under the action of servo mechanism, precise control of each filling amount, improve the product pass rate ≥98%. Professional design team based on years of accumulation of a large number of raw material particle size experimental parameters and data, according to the customer’s material characteristics, to provide the most reasonable screw parameters.

After putting the capsule into the machine module board, there is a photoelectric sensor to detect the capsule. No capsule, no filling, no tamping or unsealed.

Filling system with servo screw conveyor

Tamp the powder to make the powder surface smooth, and clean the top edge of the capsule for better sealing.

Optional uv sterilization lamp and anti-static device, clean filling, filling precision is higher.

Application

Product detail pictures:

Related Product Guide:

abide by the contract", conforms on the market requirement, joins from the market competition by its good quality likewise as provides more comprehensive and superb support for customers to let them become large winner. The pursue of the company, is definitely the clients' pleasure for China wholesale Capsule Machine Size 2 Pricelist – High Speed Primary Packaging Capsule CFM-1 Captima Filling And Sealing Machine K-Cup One Line – CAPTIMA , The product will supply to all over the world, such as: Plymouth, French, Luxemburg, Based on experienced engineers, all orders for drawing-based or sample-based processing are welcomed. We have now won a good reputation for outstanding customer service among our overseas customers. We will continue to try the best to supply you good quality products and solutions and the best service. We've been looking forward to serving you.

Problems can be quickly and effectively resolved, it is worth to be trust and working together.