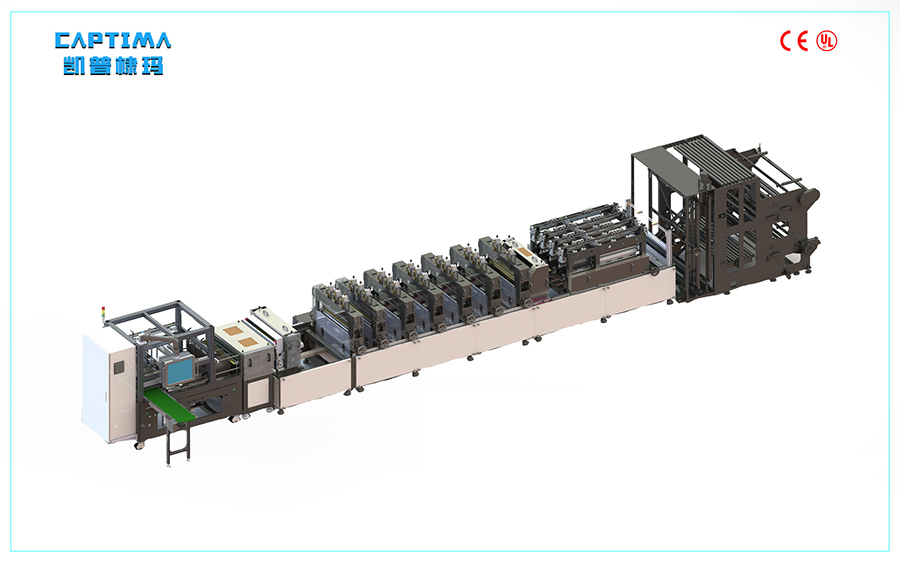

China wholesale Flexible Packaging Pouches Bag Machine Supplier – SKB700-BIBT Fully Automation Bag-in-Box with Nozzle Bag Making Machine – CAPTIMA

China wholesale Flexible Packaging Pouches Bag Machine Supplier – SKB700-BIBT Fully Automation Bag-in-Box with Nozzle Bag Making Machine – CAPTIMA Detail:

Product Features

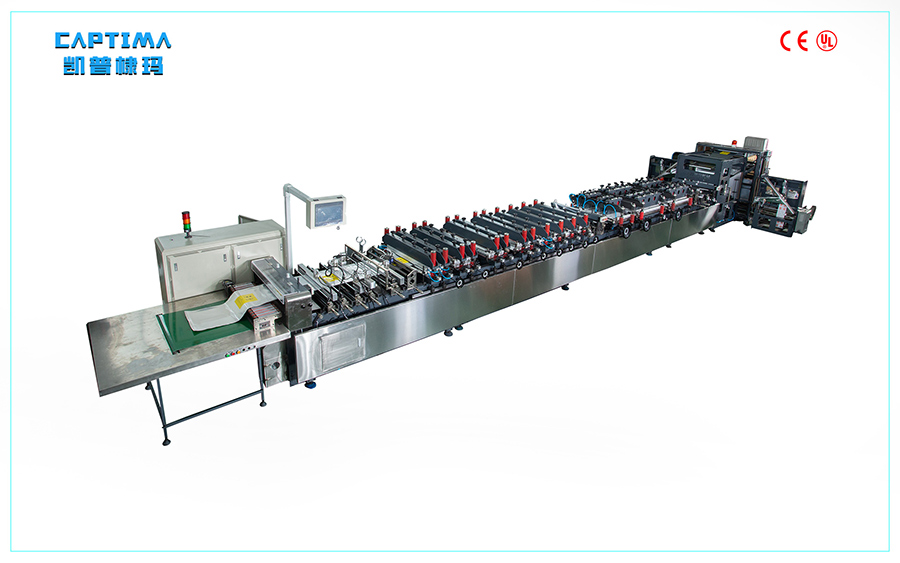

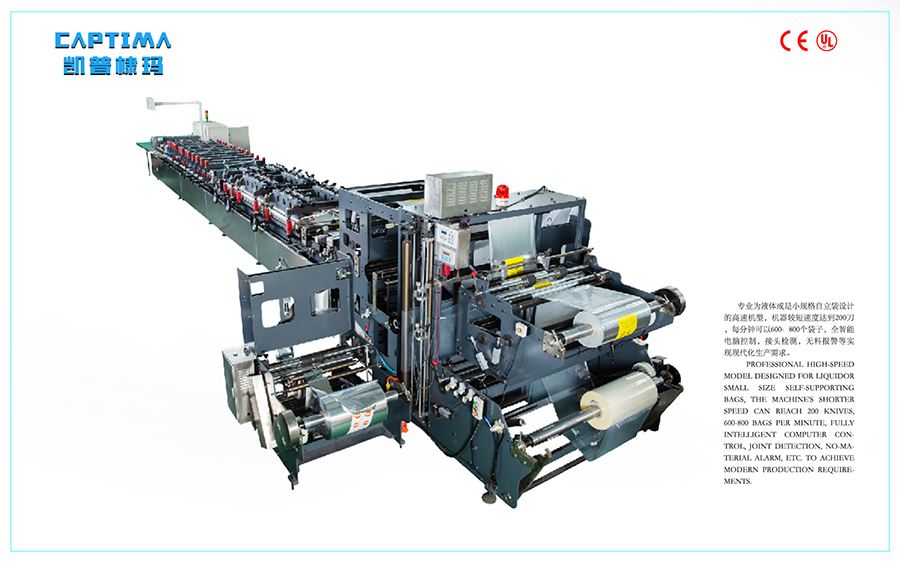

It is suitable for single material and multi-piece material combination production, solves liquid packaging and transportation and cost problems, realizes the function of fully automatic online hot pressing nozzle and gland, and the maximum production capacity is four rows.

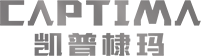

Product Picture

Sample Bag Picture

Product Packaging Scope

Machine Configuration

| Model | SKB700-BIBT Fully Automation Bag-in-Box with Nozzle Bag Making Machine | |||||||

| Optional Model | 700 | 800 | 1000 | 2000 | ||||

| Film Material | CPP,PET,OPP,PAPER and all kinds of laminating films | |||||||

| Film Size | Main film Max. Width:1200mm、 Max. Diameter:φ800mm

Middle PE film Max. Width:1200mm、 Max. Diameter:φ800mm The film size is the same for standard three side seal bags. |

|||||||

| Rewinding Form of Film | Main films Horizontal Film Axis Type·M-Plate Mode·Tension Control Magnetic Brake

Middle PE film Horizontal film axis type, M-Plate Mode·Tension Control Magnetic Brake AC Motor Driving System with inverter Detection of printing color label by color label sensor |

|||||||

| Bag-making Function | 2 lanes three side seal. 2 lanes Bag-in-Box with nozzle | |||||||

| Bag-making speed | 10-50shots/min | Unwind line Speed: | 20m/min | |||||

| Bag-making Size | Bag length:200-700mm,Bag width:200-400mm | |||||||

| Skip Feed Function | 400 mm for one time, more than 400mm, used skip feed feature, maximum is 6times | |||||||

| Bad exclusion function | At the beginning of the operation, in order to prevent the poorly sealed bags from being mixed in, set the film at an arbitrary distance from the cutter to remove the film | |||||||

| Electrical Matching | Main servo motor:1set,4KW.

Traction servo motor:3set,1.5KW—3set. Feeding AC motor:4set,0.4KW—4set. Feeding inverter:4set,0.75KW—4set. |

|||||||

| Valve Cover Matching | Vibrating Feed Head Device – 4 Sets, Fully Automatic Positioning and Conveying Device – 4 Sets

Automatic feeding control for material shortage – 4 sets, automatic pressing device – 2 sets, automatic capping device – 2 sets |

|||||||

| Electrical Matching | Total Power:

48KW,380V,50HZ |

Cooling Water:

10L/min |

Air Pressure:

0.6MPa(6Kgf/)cm² |

|||||

| Machine Dimensions | L*W*H:13000*1700*2300mm (By the selected function to determine the final size) | |||||||

|

Option function |

Fly-cutter device | Double cutter (including round corner punches). | ||||||

| Main web with registration control function | Double bottom inserting and edge inserting function | |||||||

| Double side gusset with registration control function | Six set unwinding structure | |||||||

| New Model | Batch Cutting and Rewinding Table | |||||||

Machine Parts Diagram

4 or 6 sets of constant tension control unwinding devices are used. The special part of this product is that the inner layer is composed of 2 or 4 single material PE materials. The unwinding control of PE materials must adopt close to zero tension. Mode, 4 or 6 sets of unwinding are manually loaded

All pressing is done by a separate servo motor. The pressing pressure is controlled by the servo motor. The pressing time determines that the inner and outer layer materials can be heat-sealed in the most perfect state without damaging the surface and controlling the traction force to avoid overheating. Stretching of the finished material and the quality of the final product

The flying knife device is adopted, and the running speed and cutting cycle are controlled by the servo motor, which effectively controls the ultra-wide cutting ability and the final effect

Product detail pictures:

Related Product Guide:

We are going to dedicate ourselves to providing our esteemed buyers together with the most enthusiastically thoughtful products and services for China wholesale Flexible Packaging Pouches Bag Machine Supplier – SKB700-BIBT Fully Automation Bag-in-Box with Nozzle Bag Making Machine – CAPTIMA , The product will supply to all over the world, such as: Houston, Moldova, Georgia, Since the establishment of our company, we've realized the importance of providing good quality goods and the best before-sales and after-sales services. Most problems between global suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question points they do not understand. We break down these barriers to ensure you get what you want to the level you expect, when you want it.

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!