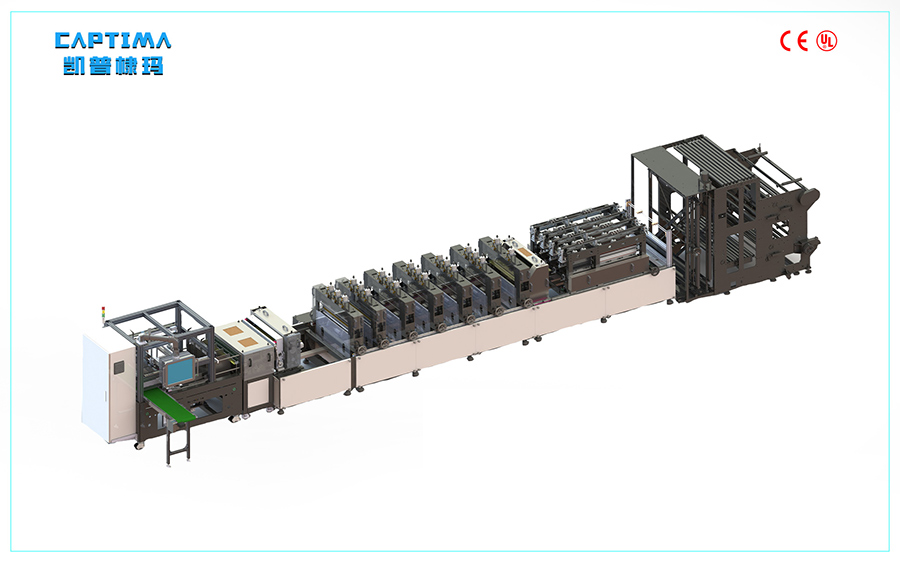

China wholesale Flexible Packaging Recycling Pouch Machine Suppliers – SKB800-IGSU Intelligence Stand Up Pouch With Zipper Bag Making Machine – CAPTIMA

China wholesale Flexible Packaging Recycling Pouch Machine Suppliers – SKB800-IGSU Intelligence Stand Up Pouch With Zipper Bag Making Machine – CAPTIMA Detail:

Product Features

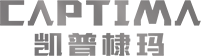

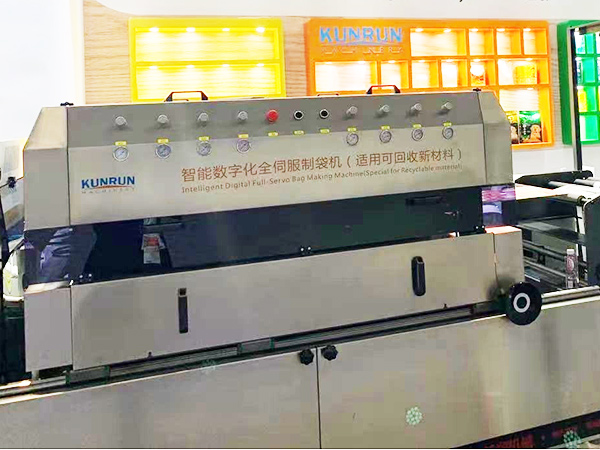

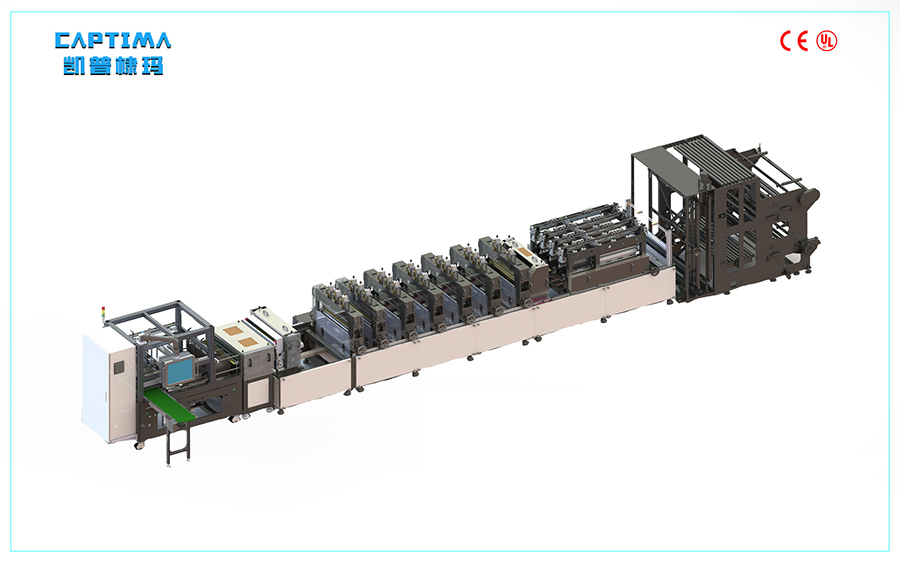

Remove the slow, easy-to-damage and non-level mechanical design of traditional machinery, reduce the quality problems caused by parts production or installation, reduce the time cost of operators and waste of raw material debugging, it is controlled by a full-servo supporting intelligent computer, and ultra-high-speed intelligent production of plastic bags , Complete recording of production data and feedback terminals, used for intelligent factory management and control, and more suitable for the production of single or recyclable new materials, and contribute a little to global environmental protection. Machine speed: 300 knives, 600-1200 bags per minute

Product Picture

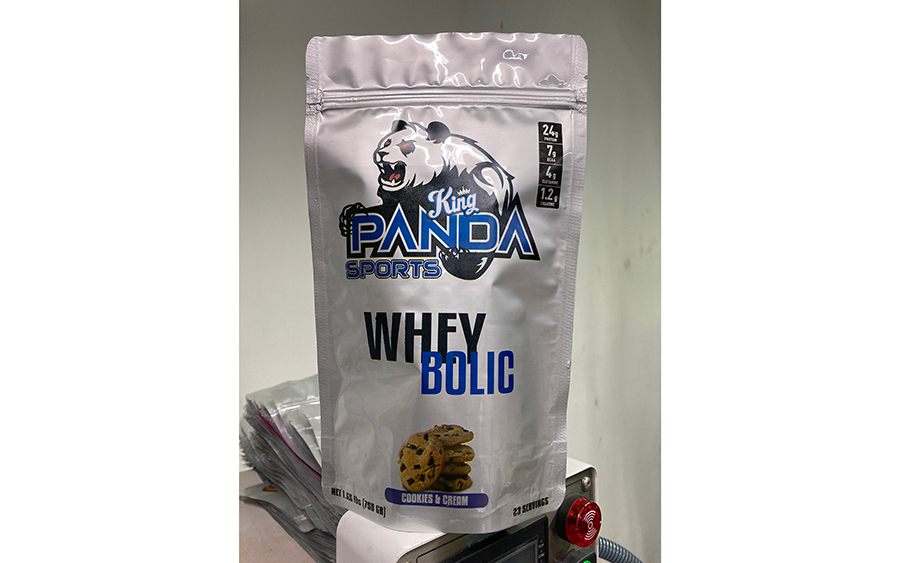

Sample Bag Picture

Product Packaging Scope

Machine Configuration

| Model: | SKB800-IGSU Intelligence Stand Up Pouch With Zipper Bag Making Machine

|

||||

| Optional Model | 600 | 800 | Customization | ||

| Film Material | CPP,PET,OPP,PAPER and all kinds of laminating films | ||||

| Film Size | Main film Max. Width:1200mm、 Max. Diameter:φ800mm

Insertion Max. Width:150mm、 Max. Diameter:φ500mm The film size is the same for standard three side seal bags. |

||||

| Rewinding Form of Film | Main films Horizontal Film Axis Type·M-Plate Mode·Tension Control Magnetic Brake

Inserted film vertical film axis type, K-plate folding bottom, tension control magnetic brake AC Motor Driving System with inverter Detection of printing color label by color label sensor |

||||

| Bag-making Function | 3 lanes three side seal, 2 lanes stand up pouch zipper bags ,2 lanes gusset stand up zipper bag | ||||

| Bag-making speed | 250shots/min | Unwind line Speed: | 70m/min | ||

| Bag-making Size: | Bag length:80-550mm, Bag width:50-400mm,Insertion depth:20-70mm | ||||

| Skip Feed Function | 400 mm for one time, more than 400mm, used skip feed feature, maximum is 6times | ||||

| Bad exclusion function | At the beginning of operation, in order to prevent the incorporation of bad heat sealing bags, a film with arbitrary distance is set from the cutting knife to remove double feeding. | ||||

| Electrical Matching | Main servo motor:1set,4KW。

Traction servo motor:4et,1.5KW—2set,1KW—2set. Feeding AC motor:3set,0.4KW—1set,0.12KW—2set. Feeding inverter:3set,0.75KW—1set,0.4KW—2set. |

||||

| Electrical Matching | Total Power:

65KW,380V,50HZ |

Cooling Water:

10L/min |

Air Pressure:

0.6MPa(6Kgf/)cm² |

||

| Machine Dimensions | L*W*H:13500*2500*2300mm (By the selected function to determine the final size) | ||||

|

Option function |

①Single line four side seal | ②Double cutter (including round corner punches). | |||

| ③Main web with non-stop function | ④side gusset with non-stop function | ||||

| ⑤ Main web with registration control function | ⑥ side gusset with registration control function | ||||

| ⑦ Fully automatic coffee valve | ⑧ Fully automatic on-line die cutting | ||||

| ⑨ Fully automatic slider zipper | ⑩CCD Cutter | ||||

| New Model | Ultra-high speed stand up pouch with zipper bag making machine (250 shots/ min)

Automatic Detection Bag Strapping Machine |

||||

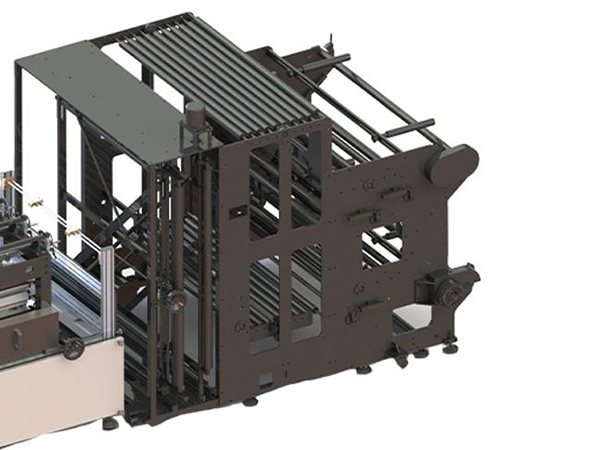

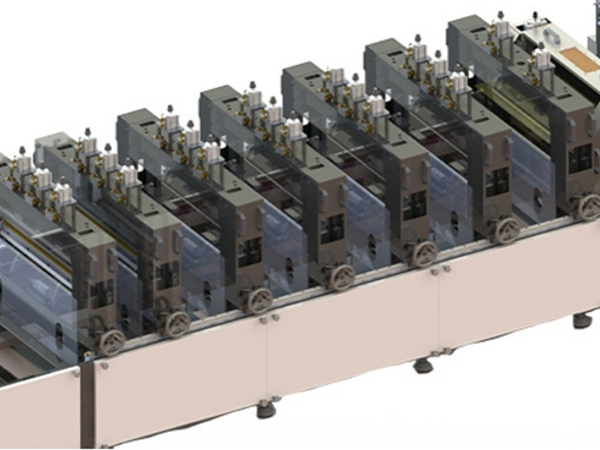

Machine Parts Diagram

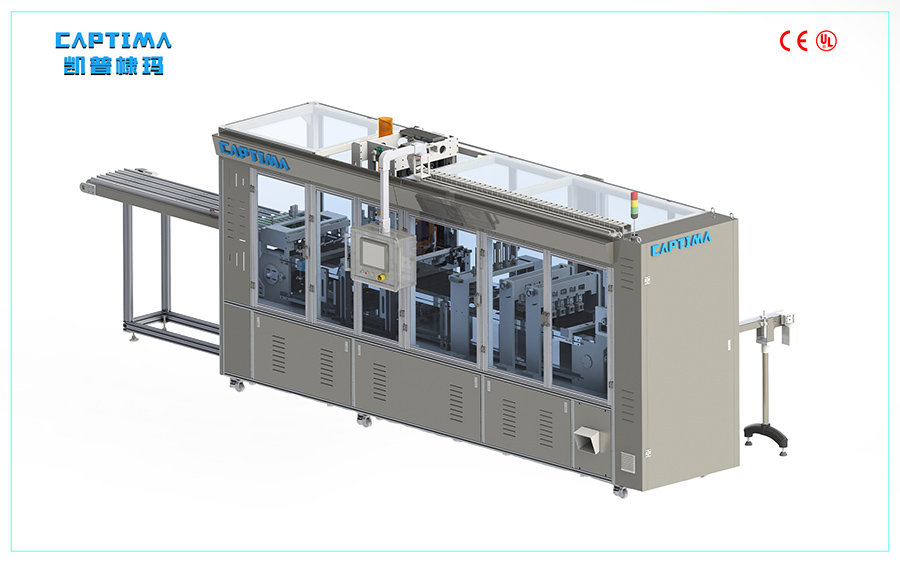

Using servo motor active unwinding structure, linear speed 90 meters per minute, reducing material traction, adapting to high-speed unwinding requirements of recyclable new materials or a single material, the main material is controlled by constant tension and non-stop unwinding, no need to stop the equipment operation , Directly update new material rolls to achieve a constant production mode without loss.

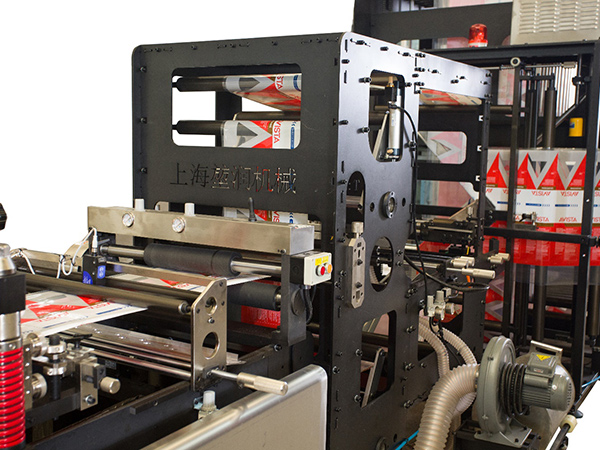

After mid-slitting of original film and become upper and down web, The cut material adopts the air pressure control of the low-friction cylinder, and the structure of the dwarfing machine body is synchronized to realize the upper, lower, left and right alignment of the two pieces of material and synchronous traction. At the same time, the tension of the upper and lower pieces of material is controlled by its own Gravity determines

The longitudinal sealing and zipper body is a one-piece structure, up and down moving structure, a single set is equipped with a separate servo motor and the servo motor controls the pressing pressure, pressing time and pressing cycle, ensuring that new materials or single materials can be recycled It can be heat-sealed in the most perfect state without damaging the surface and controlling the traction force, avoiding the stretching of super-materials and the quality of the final product, and increasing the machine speed to 300 knives per minute, achieving a production capacity of 600 bags per minute

The camera controls the double cutter structure, the high-definition lens accurately locates the cutting point, and the cutter performs high-speed and stable cutting action to ensure that the bag-shaped radius is complete and beautiful, reaching the accuracy standard of the die-cutting machine. Working speed: 300 knives per minute .

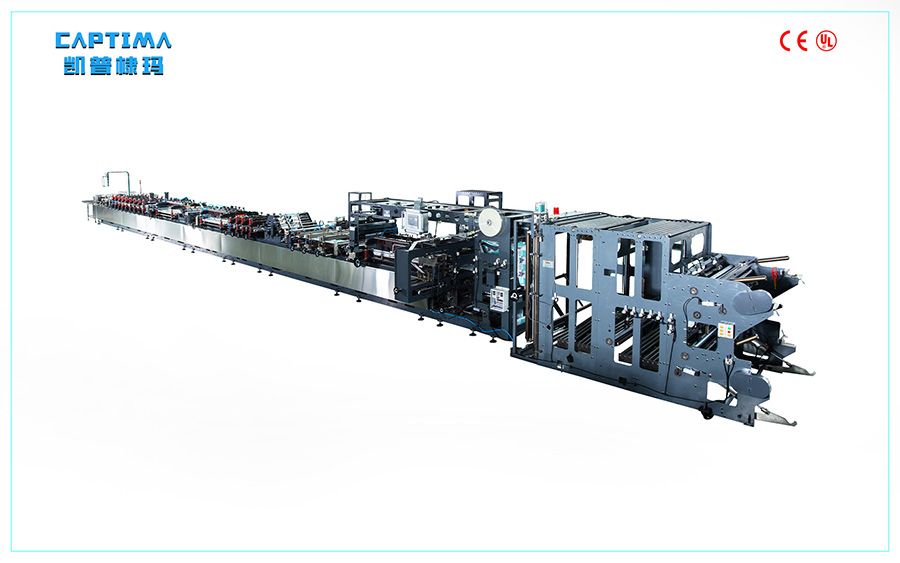

It is also equipped with the “Automatic Finished Bag Sorting Machine”, and the synchronous bag making machine realizes high-speed and precise positioning, sorting, and strapping actions, adapting to finished bags of different sizes and functions.

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for China wholesale Flexible Packaging Recycling Pouch Machine Suppliers – SKB800-IGSU Intelligence Stand Up Pouch With Zipper Bag Making Machine – CAPTIMA , The product will supply to all over the world, such as: Israel, Rwanda, Iran, All of our products comply with international quality standards and are greatly appreciated in a variety of markets around the world. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients in the near future.

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.