China wholesale High Speed Paper Bag Making Machine Manufacturers – SKB1200-BPZDN-MTD Double Lanes Box Pouch With Zipper Bag Making Machine – CAPTIMA

China wholesale High Speed Paper Bag Making Machine Manufacturers – SKB1200-BPZDN-MTD Double Lanes Box Pouch With Zipper Bag Making Machine – CAPTIMA Detail:

Product Features

At present, the widest Flat bottom pouch bag making machine in the world is suitable for the production of 20-40KG flat bottom pouch bags, which solves the technical problem of large-size packaging requiring zippers.

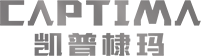

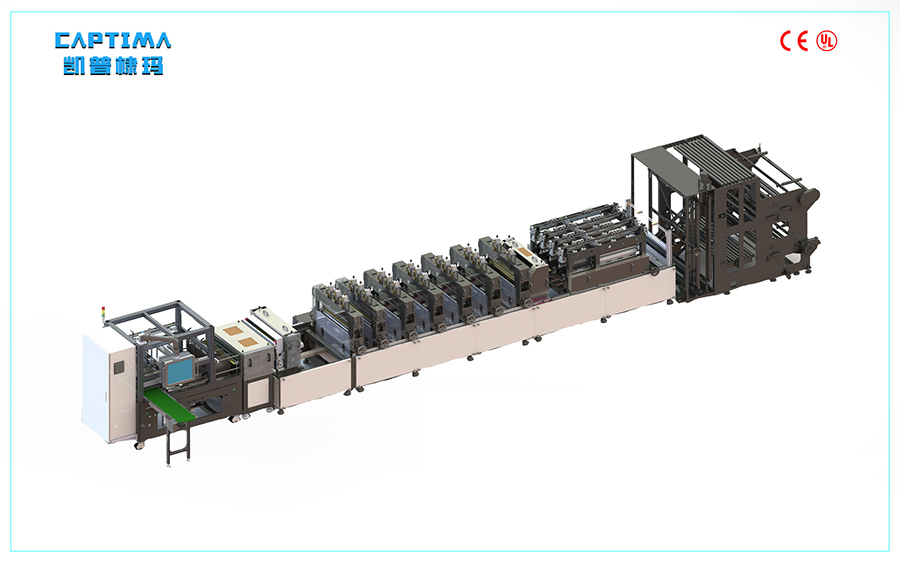

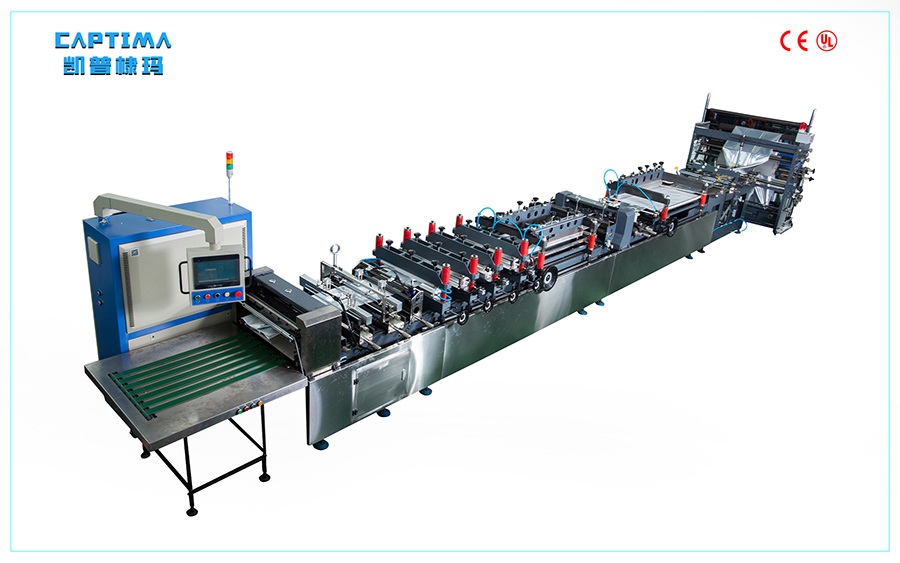

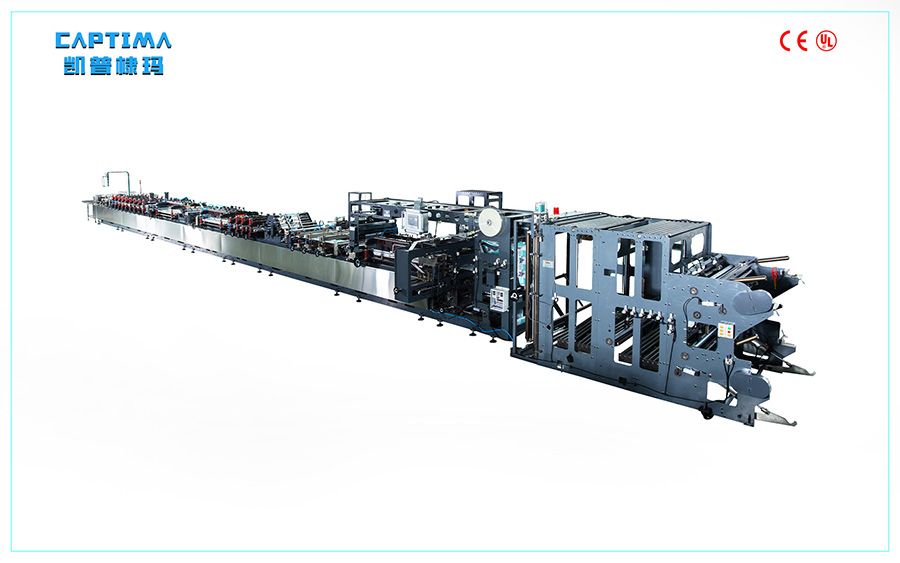

Product Picture

Sample Bag Picture

Product Packaging Scope

Machine Configuration

| Model | SKB1200-BPZDN-MTD Double Lanes Box Pouch With Zipper Bag Making Machine | ||||

| Optional Model | 1000 | 1200 | Customization | ||

| Film Material | CPP,PET,OPP,PAPER and all kinds of laminating films | ||||

| Film Size | Up film Max. Width:1200mm、Max. Diameter:φ700mm

Down film Max. Width:1200mm、Max. Diameter:φ700mm Gusset film Max. Width:450mm,Max. Diameter:φ600mm The film size is the same for standard three side seal bags. |

||||

| Rewinding Form of Main Film | Horizontal Film Axis Type • M-Plate Mode • Tension Control Magnetic Brake, Non-stop unwinding matching Automatic Joint Detection Function

Up、down film with registration control function,Position error:+-1mm. AC Motor Driving System with inverter Detection of printing color label by color label sensor |

||||

| Rewinding Form of Gusset Film | Horizontal Film Axis Type, Center Seal Forming mode, Tension Control Magnetic Brake, Non-stop unwinding matching Automatic Joint Detection Function

AC Motor Driving System with inverter Detection of printing color label by color label sensor |

||||

| Bag-making Function | 2 lanes three side seal with zipper,2 lanes box pouch with zipper,2 lanes quad flat pouch with zipper | ||||

| Bag-making speed | 75shots/min | Unwind line Speed: | 30m/min | ||

| Bag-making Size | Single: Bag length: 450-1050mm,Bag width:250-450mm,Gusset depth:40-100mm,Bottom depth:40-100mm

Double: Bag length:225-500mm,Bag width:100-300mm,Gusset depth:30-70mm,Bottom depth:30-70mm |

||||

| Bad exclusion function | At the beginning of the operation, in order to prevent the poorly sealed bags from being mixed in, set the film at an arbitrary distance from the cutter to remove the film. | ||||

| Electrical Matching | Main servo motor:1set,5KW。

Traction servo motor:6set,2KW—6set. Gusset location:1.0KW—1set,Gusset cutter servo:0.75KW—1set Gusset hotpress:1.5KW—1set Double cutter:1.5KW,0.75KW—each 1set Feeding AC motor:4set,0.4KW—4set. Feeding inverter:4set,0.75KW—4set. |

||||

| Electrical Matching | Total Power:

90KW,380V,50HZ |

Cooling Water:

10L/min |

Air Pressure:

0.6MPa(6Kgf/)cm² |

||

| Machine Dimensions | L*W*H:26000*3500*2300mm (By the selected function to determine the final size | ||||

|

Option function |

Separate bottom unwind machine | carry handle on side gusset | |||

| Fully automatic coffee valve | Fully automatic on-line die cutting | ||||

| Fully automatic slider zipper | Fly-cutter | ||||

| Fully automatic pocket zipper | |||||

| New Model | Automatic Detection Bag Strapping Machine | ||||

Machine Parts Diagram

It adopts the non-stop unwinding function of the upper and lower two pieces of main material, and the constant tension unwinding is controlled by the inverter. The double storage is up to 40 meters, without stopping the operation of the equipment, directly updating the new material roll to achieve a lossless constant production mode.

Also have the double unwind register feature and suitable for digital printing project.

The unwinding of the side gusset film ,the structure of constant tension and non-stop rewinding. The inverter controls the constant tension storage and unwinding, and the storage is up to 45 meters. The side gusset film positioning, cutting, fixed-point conveying and fixed-point hot pressing are all equipped with a separate servo motor supporting PLC. Position the photoelectric to achieve high-speed and precise fixed-point work, remove the deviation and high waste rate of artificial and old models.

The mechanical structure controls the full-automatic folding operation, realizing constant-speed and constant folding motion, and realizing the high-speed and stable production of 120 bags per minutes without deviation and no misalignment.

The camera controls the double cutter structure, the high-definition lens accurately locates the cutting point, and the cutter performs high-speed and stable cutting action to ensure that the bag-shaped radius is complete and beautiful, reaching the accuracy standard of the die-cutting machine. Working speed: 120 knives per minute .

Product detail pictures:

Related Product Guide:

Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs of China wholesale High Speed Paper Bag Making Machine Manufacturers – SKB1200-BPZDN-MTD Double Lanes Box Pouch With Zipper Bag Making Machine – CAPTIMA , The product will supply to all over the world, such as: Lithuania, Iran, Nigeria, Our Company policy is "quality first, to be better and stronger, sustainable development" . Our pursuit goals is "for society, customers, employees, partners and enterprises to seek reasonable benefit". We aspirate to do cooperate with all different the auto parts manufacturers, repair shop, auto peer , then create a beautiful future! Thank you for taking time to browse our website and we would welcome any suggestions you may have that can help us to improve our site.

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.