China wholesale Ink Filling Machine Factories – Liquid Capsule Filler CFM-2 Tea Coffee Capsule Filling Sealing Machine K-cup USA – CAPTIMA

China wholesale Ink Filling Machine Factories – Liquid Capsule Filler CFM-2 Tea Coffee Capsule Filling Sealing Machine K-cup USA – CAPTIMA Detail:

Product Features

1. Automatic rejection of defective products

2. Nitrogen filling and fresh-keeping function (residual oxygen content ≤0.8%)

3. Full servo filling system

4. Full-line non-stop feeding

5. Fixed number production function

6. Closed-loop weighing control system

7. Food contact Partially uses food grade 304

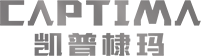

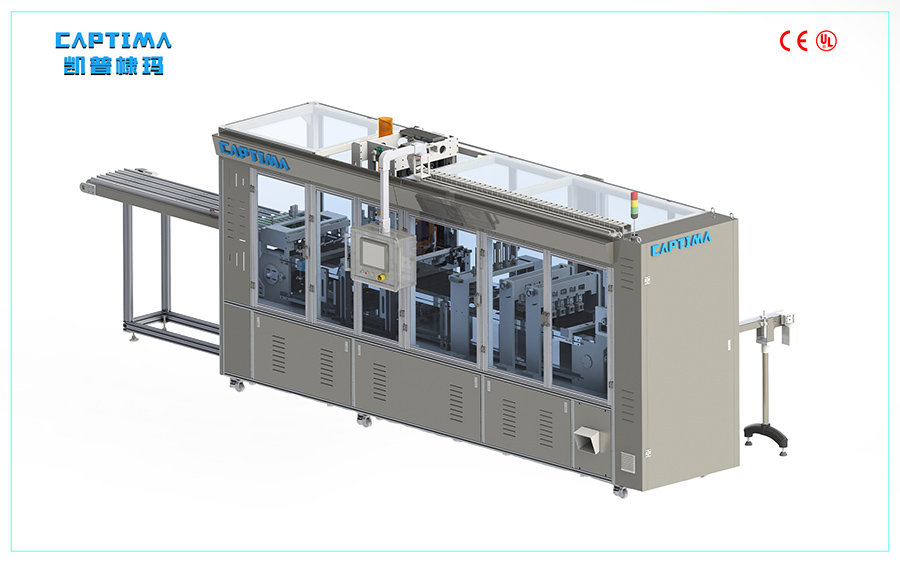

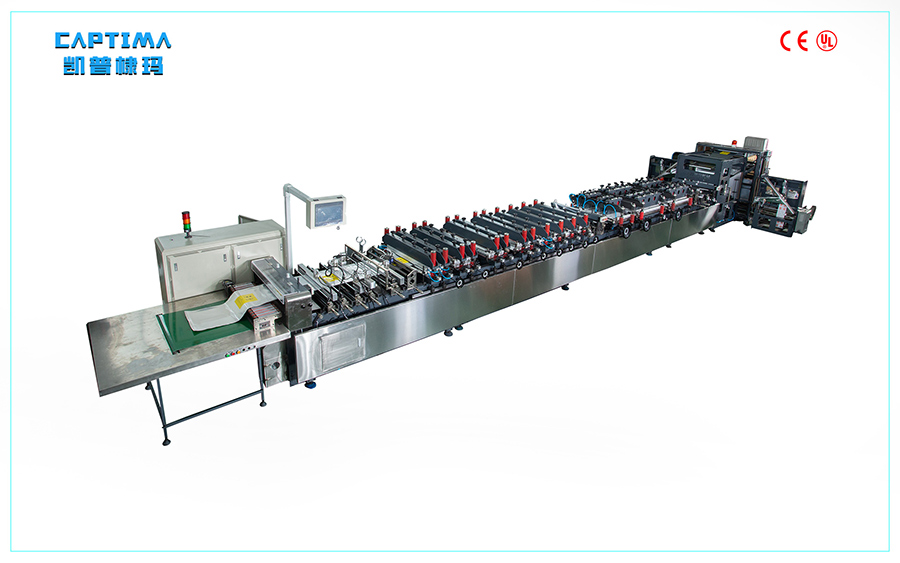

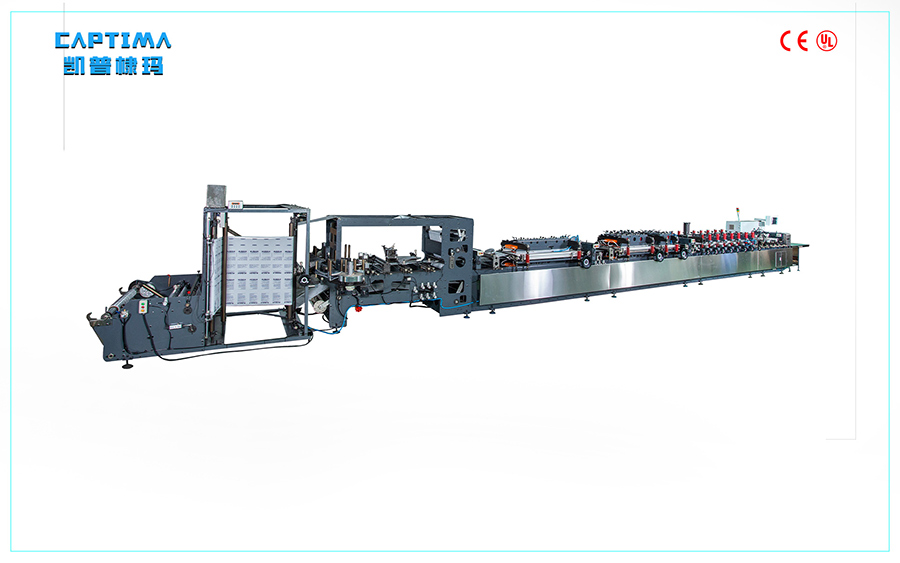

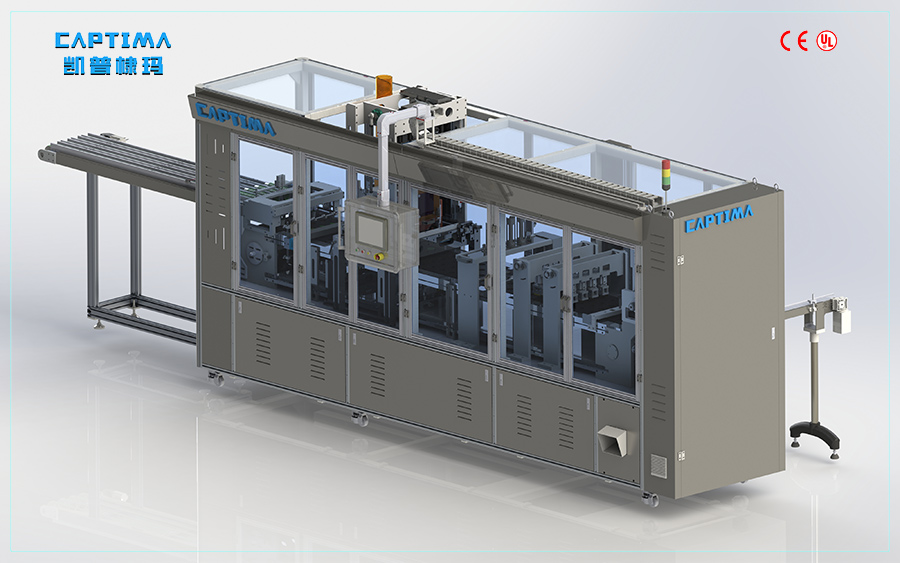

Product Picture

Sample Bag Picture

Product Packaging Scope

Machine Configuration

| Product number | CFM-2 |

| Applicable cup type | K-CUP (can be customized) |

| Sealing material | Aluminum foil film |

| Mechanical speed | 40 cups/min |

| Canned quantity | 20g |

| Canning accuracy | +-0.2g |

| Nitrogen consumption | 150L/min |

| Control System | PLC+bus communication |

| Total power | 220V/50Hz (voltage can be customized) |

| Gas demand | 0.7Mpa |

| Overall line efficiency | 160 p/m (40p/l/p) |

| Filling accuracy | 25g±0.15g (powder) |

| Filling method | Servo custom screw |

| Applicable raw material characteristics | Powder granule liquid |

Machine Parts Diagram

Weighing structure

Realizing automatic production management optimization: closed-loop weighing control system

The mechanical structure is connected by servo motor, and the weighing method is rotating up and down. The weighing precision is 0.002g, and the speed matches the canning line.

After real-time online weighing, each filling volume is adjusted by closed-loop control inside the weighing system to ensure that materials with different characteristics (humidity, viscosity, volume density) can also be filled with high accuracy. Each filling result can be recorded in the system. Data can be stored separately or connected to factory MES systems

Top membrane sealing structure

Alternative 1:

Ensure product sealing: the plate is conveyed through the tube body in the form of cutting pieces, the servo motor is connected to the mechanical structure for fixed point and timing grab, and the electric heating plate presses the lid film. Center positioning accuracy: ≤0.5mm, sealed yield: 99%.

Alternative 2:

Film forming, constant tension control unwinding mechanism, photoelectric servo positioning, the use of blade forming coil die cutting, while completing the hot pressing step, center positioning accuracy: ≤0.5mm, sealing rate: 99%.ep at the same time, center positioning accuracy: ≤0.5mm, sealing yield: 99%.

Reject defective products

Improve production quality: canned products are determined by the second weighing, and defective products are rejected mechanically by chain plate structure.

Reject defective products

Swing the output arm

Swing the output arm

Swing arm to remove the capsule, then return to packaging. Maximize labor cost savings

Application

Product detail pictures:

Related Product Guide:

Our enterprise aims to operating faithfully, serving to all of our prospects , and working in new technology and new machine frequently for China wholesale Ink Filling Machine Factories – Liquid Capsule Filler CFM-2 Tea Coffee Capsule Filling Sealing Machine K-cup USA – CAPTIMA , The product will supply to all over the world, such as: Serbia, Lahore, Boston, Now we've been sincerely consider to grant brand agent in different areas and our agents' maximum margin of profit is the most important thing we care about. Welcome all of the friends and customers to join us. We have been ready to share win-win corporation.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.