China wholesale Pet/Pe Bag Making Machine Factory – SKB700-BPZDN-MT Double Lanes Box Pouch With Zipper Bag Making Machine – CAPTIMA

China wholesale Pet/Pe Bag Making Machine Factory – SKB700-BPZDN-MT Double Lanes Box Pouch With Zipper Bag Making Machine – CAPTIMA Detail:

Product Features

Since research and development in 2008, nearly 450 automatic flat-bottom bag making machines have been sold, occupying 60% of the global market. It is equipped with an intelligent control system. The machine speed can reach 100 knives, 200 bags can be produced per minute, and the yield rate is 97%, which is very human. The simplified design theory belongs to our company’s patented product.

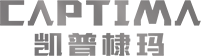

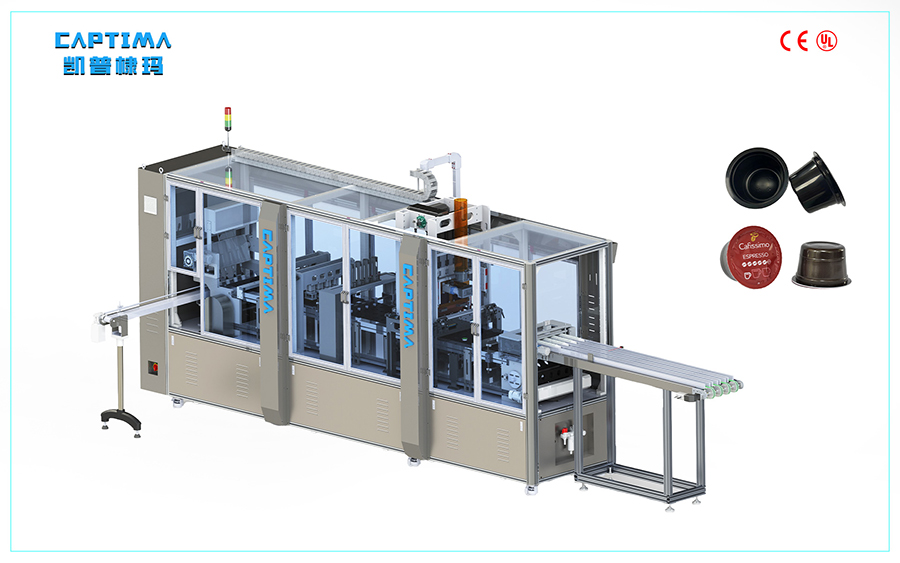

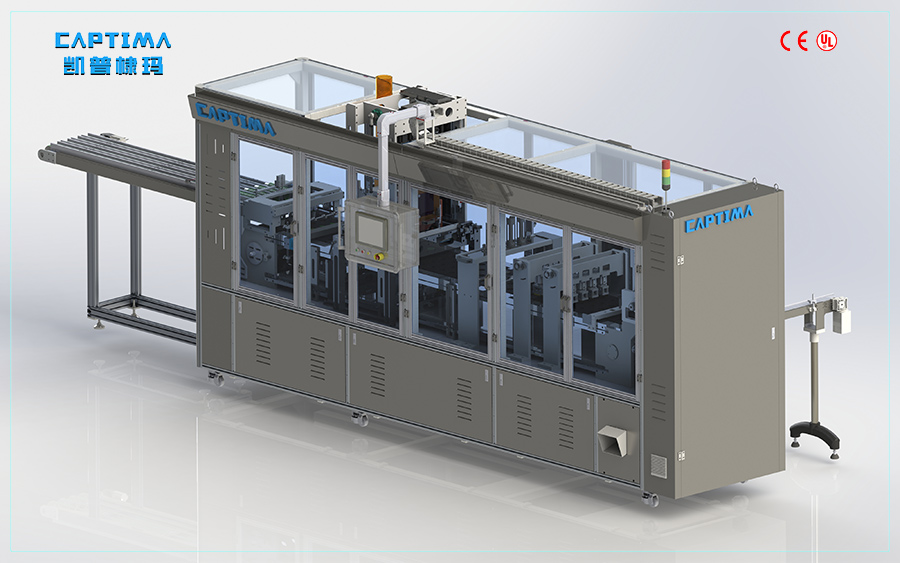

Product Picture

Sample Bag Picture

Product Packaging Scope

Machine Configuration

| Model | SKB700-BPZDN-MT Double Lanes Box Pouch With Zipper Bag Making Machine | |||||

| Optional Model | 700 | 800 | Customization | |||

| Film Material | CPP,PET,OPP,PAPER and all kinds of laminating films | |||||

| Film Size | Main film Max. Width:1200mm、Max. Diameter:φ800mm

Gusset film Max. Width:410mm,Max. Diameter:φ600mm The film size is the same for standard three side seal bags. |

|||||

| Rewinding Form of Main Film | Horizontal Film Axis Type • M-Plate Mode • Tension Control Magnetic Brake, Non-stop unwinding matching Automatic Joint Detection Function

AC Motor Driving System with inverter Detection of printing color label by color label sensor |

|||||

| Rewinding Form of Gusset Film | Horizontal Film Axis Type, Center Seal Forming mode, Tension Control Magnetic Brake, Non-stop unwinding matching Automatic Joint Detection Function

AC Motor Driving System with inverter Detection of printing color label by color label sensor |

|||||

| Bag-making Function | 2 lanes three side seal with zipper,2 lanes box pouch with zipper,2 lanes quad flat pouch with zipper | |||||

| Bag-making speed | 110shots/min | Unwind line Speed: | 30m/min | |||

| Bag-making Size | Single: Bag length:200-640mm,Bag width:100-380mm,Gusset depth:35-100mm,Bottom depth:35-100mm

Double: Bag length:120-280mm,Bag width:70-300mm,Gusset depth:25-70mm,Bottom depth:25-70mm |

|||||

| Bad exclusion function | At the beginning of operation, in order to prevent the incorporation of bad heat sealing bags, a film with arbitrary distance is set from the cutting knife to remove double feeding. | |||||

| Electrical Matching | Main servo motor:1set,5KW。

Traction servo motor:6set,1.5KW—4set,2KW—2set。 Gusset unwinding servo motor:2.0KW—1et,Gusset location:1.0KW—1set Gusset cutter :0.75KW—1set, Gusset hotpress:1.5KW—1set Double cutter:1.0KW,0.75KW—each 1set Feeding AC motor :4set,0.4KW—2set,0.2KW—2set. Feeding inverter:4set,0.75KW—2set,0.4KW—2set. |

|||||

| Electrical Matching | Total Power:

80KW,380V,50HZ |

Cooling Water:

10L/min |

Air Pressure:

0.6MPa(6Kgf/)cm² |

|||

| Machine Dimensions | L*W*H:22500*3000*2300mm (By the selected function to determine the final size) | |||||

|

Option function |

Separate bottom unwind machine | Main web with registration control function | ||||

| Fully automatic coffee valve | Fully automatic on-line die cutting | |||||

| Fully automatic slider zipper | Fully automatic pocket zipper | |||||

| Twelve side seal | carry handle on side gusset | |||||

| Fly-cutter | ||||||

| New Model | Automatic Detection Bag Strapping Machine | |||||

Machine Parts Diagram

It adopts the non-stop unwinding function of the upper and lower two pieces of main material, and the constant tension unwinding is controlled by the inverter. The double storage is up to 40 meters, without stopping the operation of the equipment, directly updating the new material roll to achieve a lossless constant production mode.

Also have the double unwind register feature and suitable for digital printing project.

The unwinding of the side gusset film ,the structure of constant tension and non-stop rewinding. The inverter controls the constant tension storage and unwinding, and the storage is up to 45 meters. The side gusset film positioning, cutting, fixed-point conveying and fixed-point hot pressing are all equipped with a separate servo motor supporting PLC. Position the photoelectric to achieve high-speed and precise fixed-point work, remove the deviation and high waste rate of artificial and old models.

The mechanical structure controls the full-automatic folding operation, realizing constant-speed and constant folding motion, and realizing the high-speed and stable production of 120 bags per minutes without deviation and no misalignment.

Product detail pictures:

Related Product Guide:

Our business promises all users of the first-class items and the most satisfying post-sale company. We warmly welcome our regular and new prospects to join us for China wholesale Pet/Pe Bag Making Machine Factory – SKB700-BPZDN-MT Double Lanes Box Pouch With Zipper Bag Making Machine – CAPTIMA , The product will supply to all over the world, such as: Iraq, Uzbekistan, San Francisco, Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it. Faster delivery time and the product you want is our Criterion .

We have been looking for a professional and responsible supplier, and now we find it.