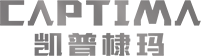

China wholesale Sa9 Capsule Filling Machine Factories – Coffee CFM-2 Nespresso Coffee Pod Filling And Sealing Machine Powder Packaging – CAPTIMA

China wholesale Sa9 Capsule Filling Machine Factories – Coffee CFM-2 Nespresso Coffee Pod Filling And Sealing Machine Powder Packaging – CAPTIMA Detail:

Product Features

1. Automatic rejection of defective products

2. Nitrogen filling and fresh-keeping function (residual oxygen content ≤0.8%)

3. Full servo filling system

4. Full-line non-stop feeding

5. Fixed number production function

6. Closed-loop weighing control system

7. Food contact Partially uses food grade 304

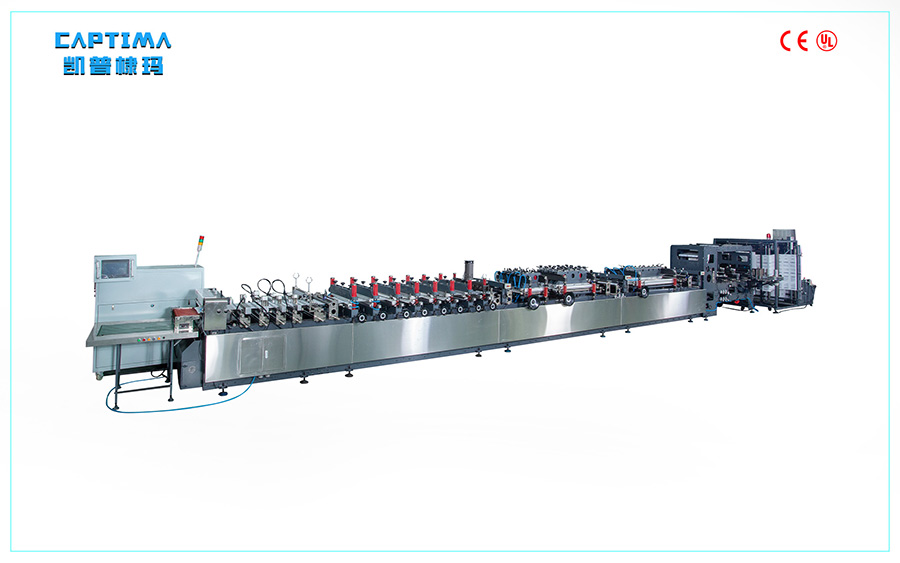

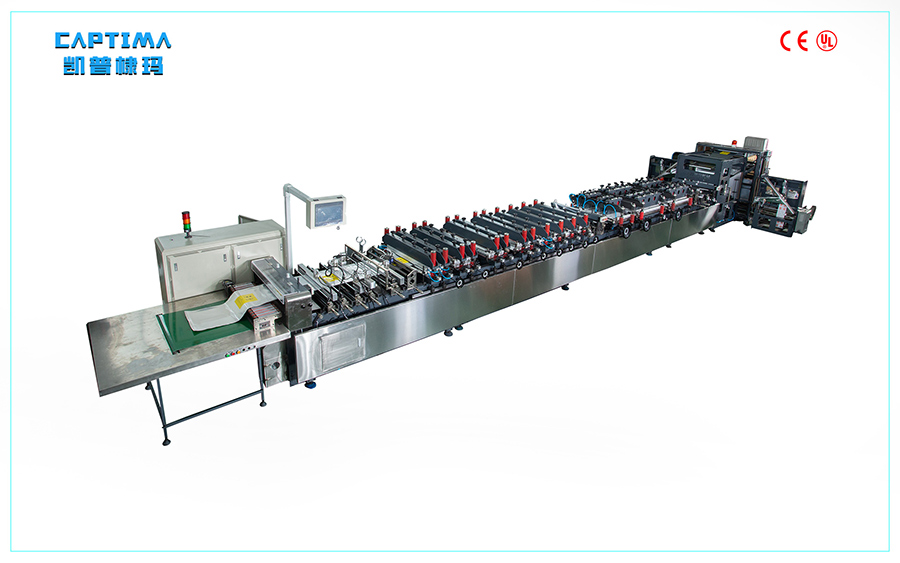

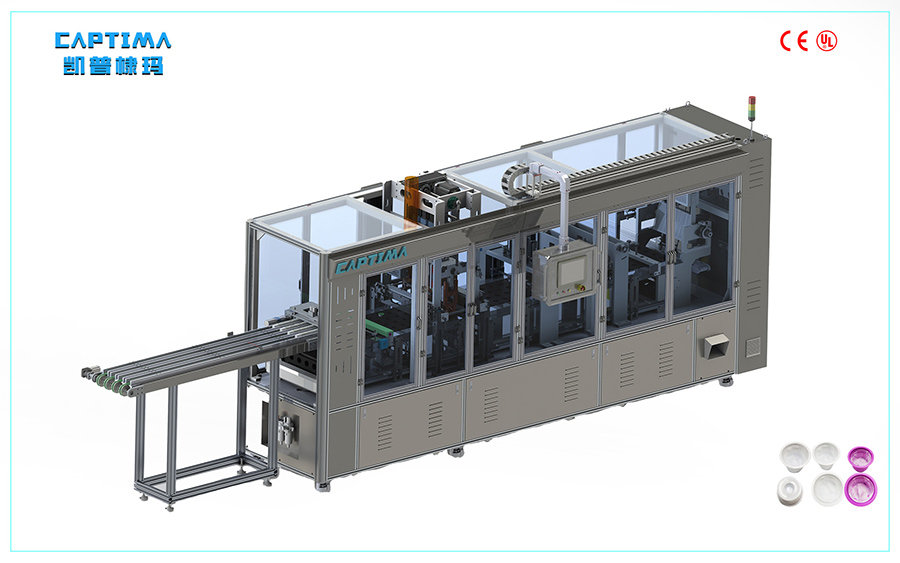

Product Picture

Sample Bag Picture

Product Packaging Scope

Machine Configuration

| Product number | CFM-2 |

| Applicable cup type | Nespresso (customizable) |

| Sealing material | Aluminum foil film |

| Mechanical speed | 35 cups/min |

| Canned quantity | 15-20g |

| Canning accuracy | ±0.2g |

| Nitrogen consumption | 150L/min |

| Filter paper material | PP fiber + wood pulp |

| Drain pan | custom made |

| Control System | PLC+bus communication |

| Total power | 220V/50Hz (voltage can be customized) |

| Gas demand | 0.7Mpa |

| Overall line efficiency | 160 p/m (40p/l/p) |

| Filling method | Servo custom screw |

| Applicable raw material characteristics | Powder granule liquid |

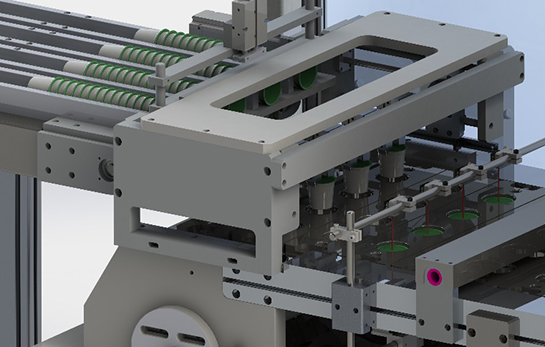

Machine Parts Diagram

1. Drop Cups Structure

Option 1:

Straight-line drop cups pass through the straight-line feed tube, each tube working time is only 15 minutes (estimated 300-400 cups), low material level automatic alarm call through buzzer, manual feeding.

Option 2:

Horizontal conveying cup body structure, 0-shaped belt conveying is controlled by a discharge motor, machine speed is synchronized with the speed of the canning line body, the storage structure adopts a warehouse body to save the manual feeding cycle and time to the greatest extent, and can achieve a single feeding Time is controlled at every 1.5 hours

Option 3:

Centrifugal disc structure, rotating conveying synchronous canning line speed, the storage structure adopts the silo body to save the manual feeding cycle and time to the greatest extent, and can achieve a single feeding time controlled at every 3 hours, which is suitable for “fully automatic Production line demand”.

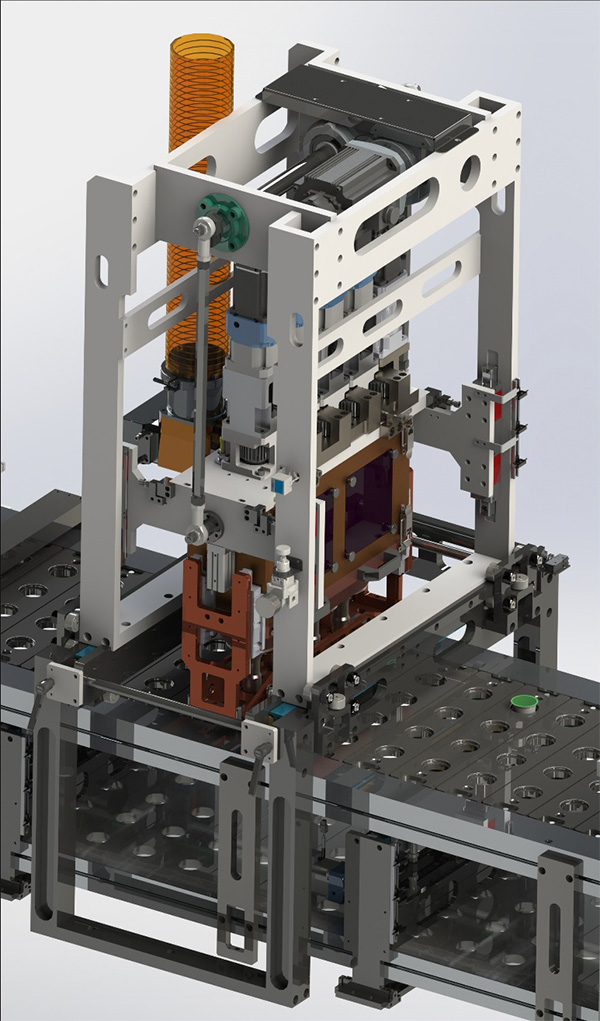

2. Weighing Structure

Closed loop weighing control system

The mechanical structure is connected through the servo motor, the weighing mode of up and down rotation, weighing accuracy: 0.002g, and the speed matches the canned line body.

After real-time online weighing, through the closed-loop control inside the weighing system, each filling volume is adjusted to ensure that materials with different characteristics (humidity, viscosity, bulk density) can also be filled with high precision. And can record every filling result in the system. The data can be stored separately or connected to the factory MES system to realize automatic production management optimization.

3. Filling Structure

Full servo screw filling system

The filling system adopts full servo drive control, only need to manually set the filling volume, without complicated settings to achieve the purpose of one-key parameter adjustment. Under the action of the servo, the filling volume of each time is accurately controlled, and the product straight-through rate is ≥98%. The professional design team provides the most reasonable screw parameters according to the customer’s material characteristics based on the large amount of experimental parameters and data accumulated over the years for the size of the raw material particles.

After the capsule were placed inside the machine module plates, there’s a photoelectric sensor to detect the capsules. No capsules, no filling, no tamping or not sealing.

With servo auger filling system

With powder tamping to flat the powder surface and clean the capsules top rim for a better sealing effect.

With optional UV sterilization lamp and anti-static device for clean filling and better filling accuracy.

4. Top Film Sealing Structure

Option 1:

In the form of the cut sheet, the sheet is conveyed through the pipe body, and the servo motor is connected to the mechanical structure for fixed-point and timing grabbing, and the cup cover film is pressed by the electric heating plate. The center positioning accuracy: ≤0.5mm, sealed product Rate: 99%.

Option 2:

Roll film form, constant tension control unwinding mechanism, photoelectric servo positioning, using blade form to carry out coil die cutting, and complete the hot pressing step at the same time, center positioning accuracy: ≤0.5mm, sealing yield: 99%.

5. Rejection Of Defective Products

The canned products are determined by the second weighing, and the defective products are mechanically rejected by the chain plate structure.

5. Rejection Of Defective Products

6. Swing Output Armer

6. Swing Output Armer

Swing armer to pickup the capsule out, then return to packaging.

Application

Product detail pictures:

Related Product Guide:

With this motto in mind, we've got become among essentially the most technologically innovative, cost-efficient, and price-competitive manufacturers for China wholesale Sa9 Capsule Filling Machine Factories – Coffee CFM-2 Nespresso Coffee Pod Filling And Sealing Machine Powder Packaging – CAPTIMA , The product will supply to all over the world, such as: Boston, Mauritius, Marseille, Welcome any of your inquiries and concerns for our products. We look forward to establishing a long-term business relationship with you in the near future. Contact us today. We are the first business partner for you!

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!