China wholesale Semi Automatic Encapsulation Machine Factories – Super Instant Coffee CFM-8 Blacksheep K-CUP servo filling machine – CAPTIMA

China wholesale Semi Automatic Encapsulation Machine Factories – Super Instant Coffee CFM-8 Blacksheep K-CUP servo filling machine – CAPTIMA Detail:

Product Features

. Speed: up to 290 capsules/min

. 8lanes

. Possibility of integrated vertical flow-wrappers

. Sliding-out dosing unit for cleaning and maintenance

. Servo-driver machine

. Quality control system

. Special projects

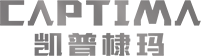

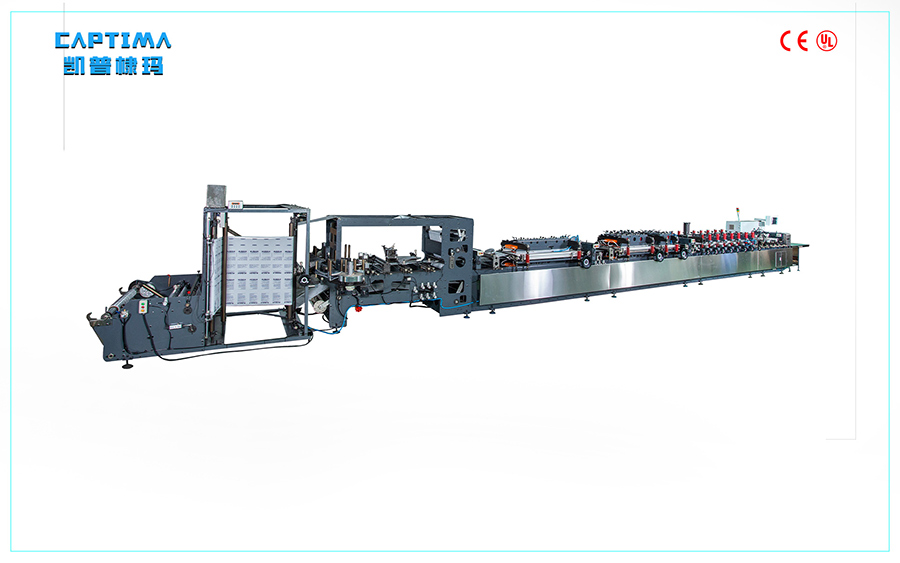

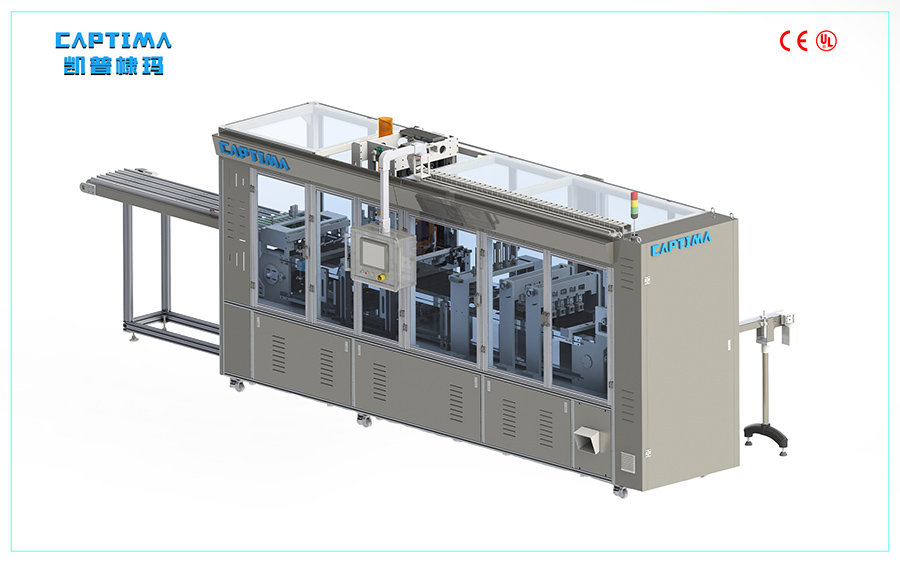

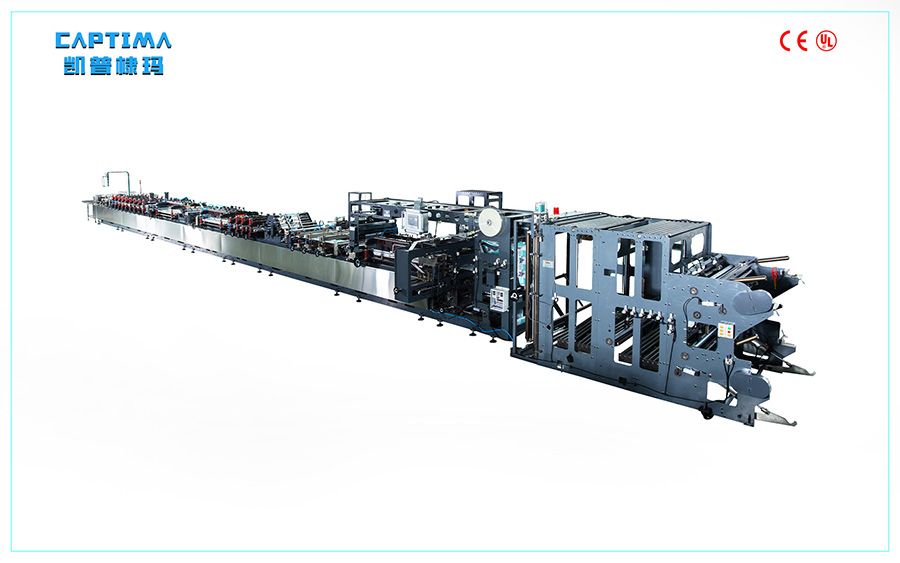

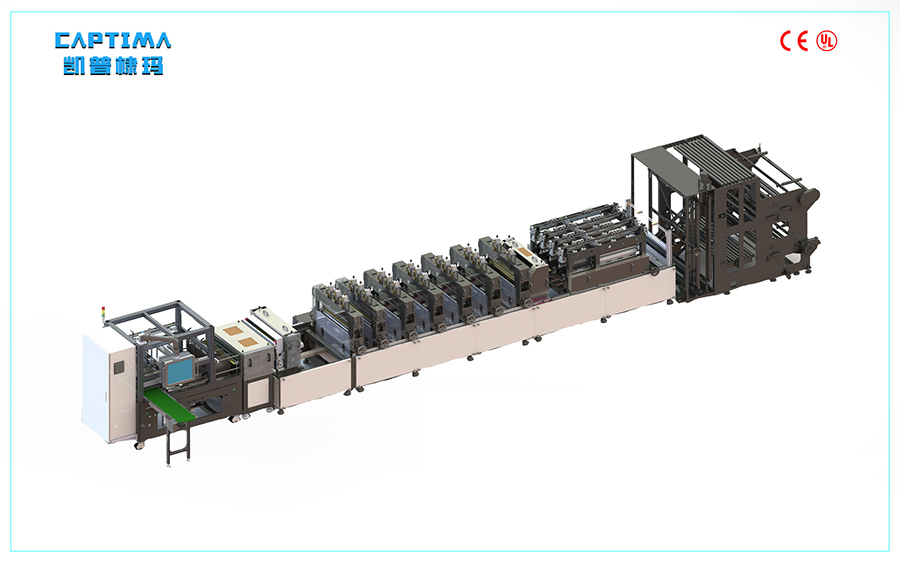

Product Picture

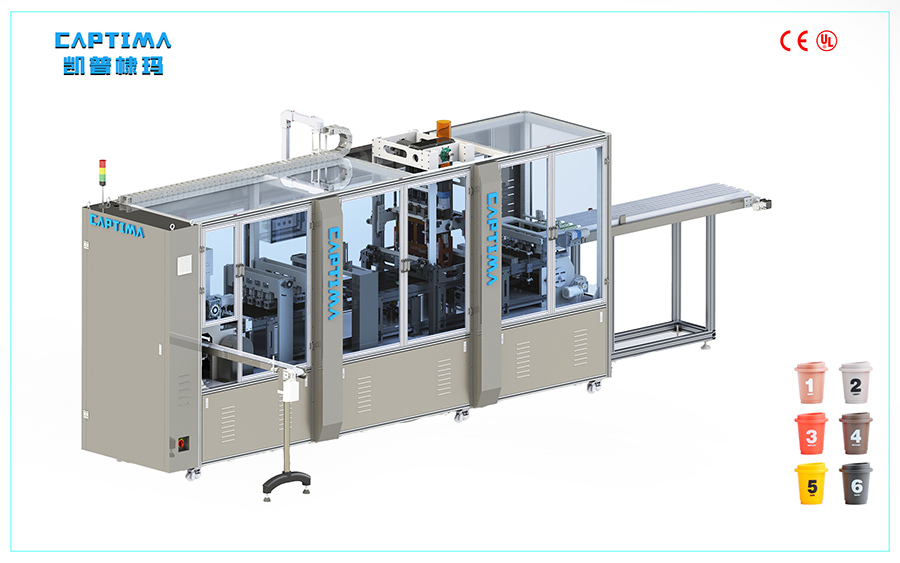

Sample Bag Picture

Product Packaging Scope

Machine Configuration

| Product number | CFM-8 |

| Applicable cup type | K-CUP (can be customized) |

| Sealing material | Pre-cut aluminum foil film |

| Filter paper material | PP fiber + wood pulp |

| Control System | PLC+bus communication |

| Total power | 220V/50Hz (voltage can be customized) |

| Gas demand | 0.7Mpa |

| Overall line efficiency | 160 p/m (40p/l/p) |

| Filling accuracy | 6g±0.15g (powder) |

| Filling method | Servo custom screw |

| Applicable raw material characteristics | Powder granule liquid |

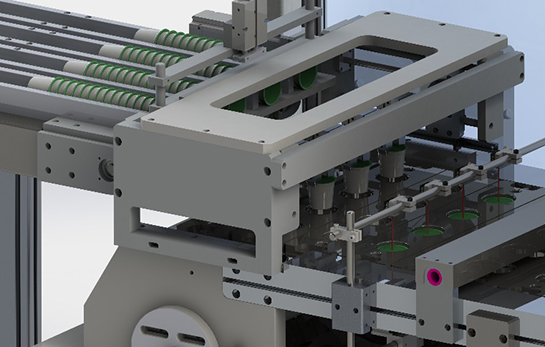

Machine Parts Diagram

Structure of the drip cup

Alternative 1

Straight drop cup through the straight feed pipe, (estimated 300-400 cups) the working time is only 15 minutes, low material level automatic alarm through the buzzer call, manual feed.

Alternative 2

Our products are horizontal conveying cup body structure, using type 0 belt conveying by unloading motor control, machine speed can be synchronized with the canned line speed, storage structure adopts warehouse structure, the maximum saving of manual feeding cycle and time, and can achieve a single feeding time control in 1.5 hours, very fast.

Alternative 3

Centrifugal disc structure, rotating conveying synchronous canned line speed, storage structure adopts bin body, the maximum saving of manual feeding cycle and time, can realize every 3 hours to control the feeding time, suitable for “automatic production line demand”.

Weighing structure

Realizing automatic production management optimization: closed-loop weighing control system.

The mechanical structure is connected by servo motor, and the weighing method is rotating up and down. The weighing precision is 0.002g, and the speed matches the canning line.

After real-time online weighing, each filling volume is adjusted by closed-loop control inside the weighing system to ensure that materials with different characteristics (humidity, viscosity, volume density) can also be filled with high accuracy.

Application

Product detail pictures:

Related Product Guide:

Quality comes first; service is foremost; business is cooperation" is our business philosophy which is constantly observed and pursued by our company for China wholesale Semi Automatic Encapsulation Machine Factories – Super Instant Coffee CFM-8 Blacksheep K-CUP servo filling machine – CAPTIMA , The product will supply to all over the world, such as: Jordan, Comoros, Serbia, We always adhere to follow the honesty, mutual benefit, common development, after years of development and the tireless efforts of all staff, now has perfect export system, diversified logistics solutions, thorough meet customer shipping, air transport, international express and logistics services. Elaborate one-stop sourcing platform for our customers!

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.