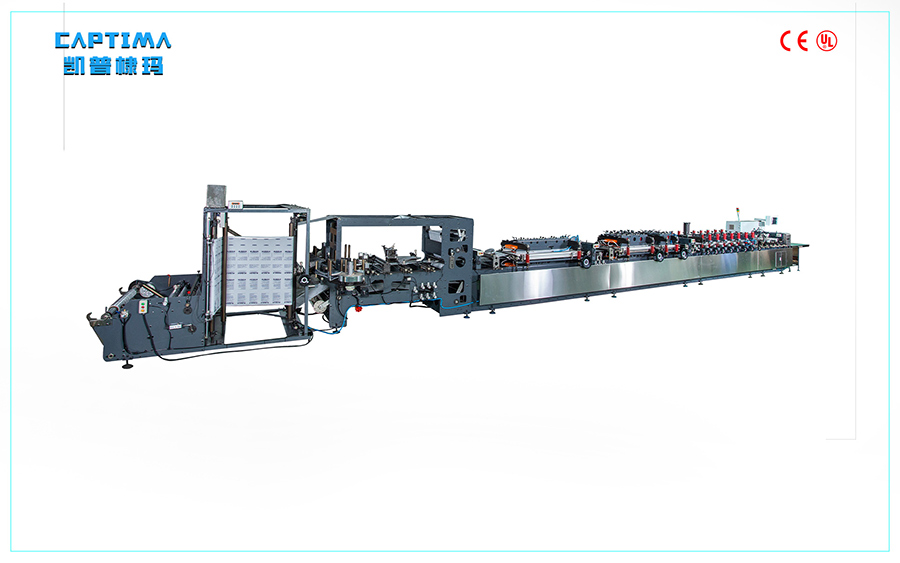

SKB600-TSGZ-T High Speed Stand Up With Zipper Bag Making Machine

Video

Product Features

The general standard bag making machine in the packaging market realizes 5 types of bag-shaped machines with the same machine speed: 200, which can produce 300-800 bags per minute.

Product Picture

Sample Bag Picture

Product Packaging Scope

Machine Configuration

| Model: | SKB600-TSGZ-T High Speed Stand Up With Zipper Bag Making Machine | ||||

| Optional Model: | 600 | 800 | Customization | ||

| Film Material: | CPP,PET,OPP,PAPER and all kinds of laminating films | ||||

| Film Size: | Main film Max. Width:1200mm、 Max. Diameter:φ800mm

Insertion Max. Width:150mm、 Max. Diameter:φ500mm The film size is the same for standard three side seal bags. |

||||

| Rewinding Form of Film: | Main films Horizontal Film Axis Type·M-Plate Mode·Tension Control Magnetic Brake

Inserted film vertical film axis type, K-plate folding bottom, tension control magnetic brake AC Motor Driving System with inverter Detection of printing color label by color label sensor |

||||

| Bag-making Function: | 3 lanes three side seal, 2 lanes stand up pouch zipper bags and single line gusset stand up zipper bag | ||||

| Bag-making speed: | 200shots/min | Unwind line Speed: | 40m/min | ||

| Bag-making Size: | Bag length:80-550mm, Bag width:50-400mm,Insertion depth:20-70mm | ||||

| Skip Feed Function: | 400 mm for one time, more than 400mm, used skip feed feature, maximum is 6times | ||||

| Bad exclusion function: | At the beginning of operation, in order to prevent the incorporation of bad heat sealing bags, a film with arbitrary distance is set from the cutting knife to remove double feeding. | ||||

| Electrical Matching: | Main servo motor:1set,4KW。

Traction servo motor:4et,1.5KW—2set,1KW—2set. Feeding AC motor:3set,0.4KW—1set,0.12KW—2set. Feeding inverter:3set,0.75KW—1set,0.4KW—2set. |

||||

| Electrical Matching: | Total Power:

65KW,380V,50HZ |

Cooling Water:

10L/min |

Air Pressure:

0.6MPa(6Kgf/)cm² |

||

| Machine Dimensions: | L*W*H:13500*2500*2300mm (By the selected function to determine the final size) | ||||

|

Option function: |

Single line four side seal | Double cutter (including round corner punches). | |||

| Main web with non-stop function | side gusset with non-stop function | ||||

| Main web with registration control function | side gusset with registration control function | ||||

| Fully automatic coffee valve | Fully automatic on-line die cutting | ||||

| Fully automatic slider zipper | CCD Cutter | ||||

| New Model: | Ultra-high speed stand up pouch with zipper bag making machine (250 shots/ min)

Automatic Detection Bag Strapping Machine |

||||

Machine Parts Diagram

The constant tension unwinding is controlled by the frequency converter, and the double storage is up to 40 meters. There is no need to stop the operation of the equipment, and the new material coil can be directly updated to achieve a lossless constant production mode. The main material can increase the pattern function, suitable for digital printer mode

After mid-slitting of original film and become upper and down web, The cut material adopts a single high-tension or synchronized low-tension fuselage structure to realize the up, down, left and right alignment of the two pieces of material and synchronize traction to achieve the highest speed of the tension control

The longitudinal seal adopts a split structure to achieve easier operability and match all specifications of plastic bag hot pressing, and solve the problem of butt joints caused by traditional hot pressing. The left and right sides adopt upper and lower movable structures to facilitate high-frequency pressing at the bottom of the self-supporting bag. need.

The horizontal seal adopts multiple sets of high pressure and low temperature forms, which is suitable for low temperature and high speed production of different thicknesses and different materials. The system is updated to a mode that increases a certain range of speed without increasing the temperature, reducing the work steps of the operator and saving debugging time

The camera controls the double cutter structure, the high-definition lens accurately locates the cutting point, and the cutter performs high-speed and stable cutting action to ensure that the bag-shaped radius is complete and beautiful, reaching the accuracy standard of the die-cutting machine. Working speed: 200cuts per minute .