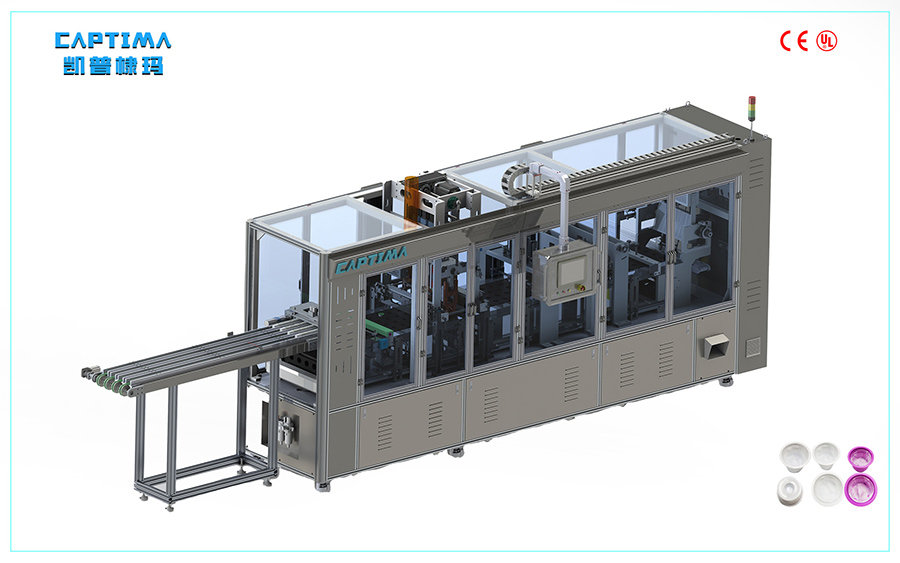

Holiday Blend CFM-4 Starbucks K-CUP Ground Coffee Powder Capsule Filling Machine

Product Features

1. Automatic rejection of defective products

2. Nitrogen filling and fresh-keeping function (residual oxygen content ≤0.8%)

3. Full servo filling system

4. Full-line non-stop feeding

5. Fixed number production function

6. Closed-loop weighing control system

7. Food contact Partially uses food grade 304

Product Picture

Sample Bag Picture

Product Packaging Scope

Machine Configuration

| Product number | CFM-4 |

| Applicable cup type | K-CUP (can be customized) |

| Sealing material | Online aluminum foil film |

| Filter paper material | PP fiber + wood pulp |

| Control System | PLC+bus communication |

| Total power | 220V/50Hz (voltage can be customized) |

| Gas demand | 0.7Mpa |

| Overall line efficiency | 160 p/m (40p/l/p) |

| Filling accuracy | 15g±0.15g (powder) |

| Filling method | Servo custom screw |

| Applicable raw material characteristics | Powder granule liquid |

Machine Parts Diagram

Weighing structure

Realizing automatic production management optimization: closed-loop weighing control system

The mechanical structure is connected by servo motor, and the weighing method is rotating up and down. The weighing precision is 0.002g, and the speed matches the canning line.

After real-time online weighing, each filling volume is adjusted by closed-loop control inside the weighing system to ensure that materials with different characteristics (humidity, viscosity, volume density) can also be filled with high accuracy. Each filling result can be recorded in the system. Data can be stored separately or connected to factory MES systems

Reject defective products

Improve production quality: canned products are determined by the second weighing, and defective products are rejected mechanically by chain plate structure.

Reject defective products

Swing the output arm

Swing the output arm

Swing arm to remove the capsule, then return to packaging. Maximize labor cost savings

Application